Digital Age: What Are the Most Effective Quality Tools?

In the digital era, the implementation of technological tools is essential to ensure and enhance the quality of processes and services within organizations. Companies face an ever-changing landscape where quality is no longer just an option but a strategic imperative for success. Technology has emerged as a fundamental ally in quality management, offering tools that optimize processes, increase efficiency, and enable new levels of excellence.

Below are some of the most effective quality tools and their impact on quality management in the Digital Era:

1. Electronic Quality Management Systems (eQMS)

eQMS are technological solutions designed to manage, monitor, and continuously improve quality processes. These systems offer significant advantages, such as process automation, which reduces human error and facilitates informed decision-making. Additionally, they promote continuous improvement by providing accurate and real-time data on quality process performance.

They offer functionalities such as:

- Workflow Automation: Streamlines repetitive tasks and frees up time for strategic activities.

- Document Management: Centralizes and organizes relevant quality documents, facilitating access and control.

- Data Analysis: Allows real-time collection, analysis, and interpretation of quality data, identifying improvement areas and making timely decisions.

- Non-Conformance Management: Facilitates the identification, recording, and resolution of non-conformances, promoting continuous improvement.

2. Quality Inspection Software

These digital tools enable more efficient and accurate quality inspections. They offer functions such as:

- Digital Checklists: Guide inspectors through the review process, ensuring no critical points are missed.

- Real-Time Data Capture: Allows immediate recording of inspection data, eliminating the need for manual transcriptions.

- Image and Video Analysis: Utilizes artificial intelligence techniques to analyze product images and videos, identifying defects and anomalies with greater precision.

- Automated Report Generation: Creates detailed reports on inspection results, facilitating follow-up and decision-making.

3. Big Data and Analytics Tools

Big Data and analytics tools allow companies to leverage the large amounts of data generated in their processes to gain valuable insights into quality. These tools can:

- Identify Patterns and Trends: Reveal patterns and trends in quality data, allowing potential problems to be anticipated and preventive measures taken.

- Segment Data: Segment data by product, production line, customer, or other relevant criteria for deeper analysis.

- Visualize Data: Present quality data visually and comprehensibly, making it easier to identify improvement areas.

4. Project Management Software

Project management tools are essential for planning, executing, and monitoring quality-related projects. They offer functionalities such as:

- Objective and Scope Definition: Clearly establish project objectives and scope, ensuring all stakeholders are aligned.

- Task and Resource Management: Allow efficient assignment of tasks, setting deadlines, and managing resources.

- Progress Tracking: Monitor project progress, identifying deviations and taking corrective actions when necessary.

- Risk Management: Facilitate the identification, assessment, and mitigation of risks that may affect project quality.

5. Collaboration Platforms

Collaboration platforms foster teamwork and effective communication among the various departments involved in quality management. These tools allow:

- Document and File Sharing: Facilitate the exchange of relevant quality information between different teams.

- Real-Time Communication: Enable instant communication among team members, speeding up problem resolution and decision-making.

- Forum and Discussion Management: Create virtual spaces for discussion and exchange of ideas on quality-related topics.

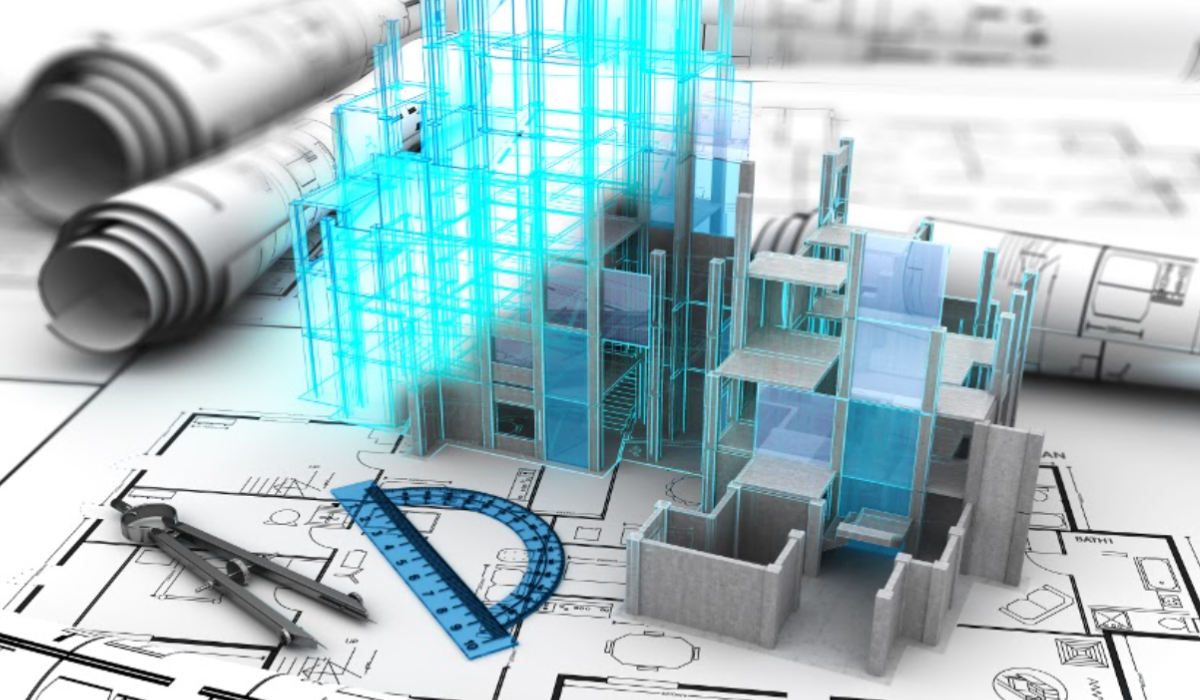

6. Digital Twins as a Quality Tool

Digital twins have become a fundamental tool for quality management in the digital era. By simulating the behavior of physical assets in different scenarios, companies can identify and prevent failures before they occur, reducing repair costs and improving product or service quality.

Additionally, digital twins facilitate continuous monitoring of the physical assets’ status, allowing for timely detection of deviations from quality standards and corrective actions.

In short, digital twins are an essential tool for companies looking to improve the quality of their products and services, optimize their processes, and make informed decisions in the digital era.

In conclusion, the Digital Era offers a wide range of effective quality tools that allow companies to optimize their processes, improve efficiency, and achieve new levels of excellence. The strategic implementation of these tools, along with a solid quality culture, can be a key differentiating factor for success in an increasingly competitive market.

JOIN THE NEW REALITY!