Las 11 Claves para Optimizar tus Proyectos con Simulación Digital

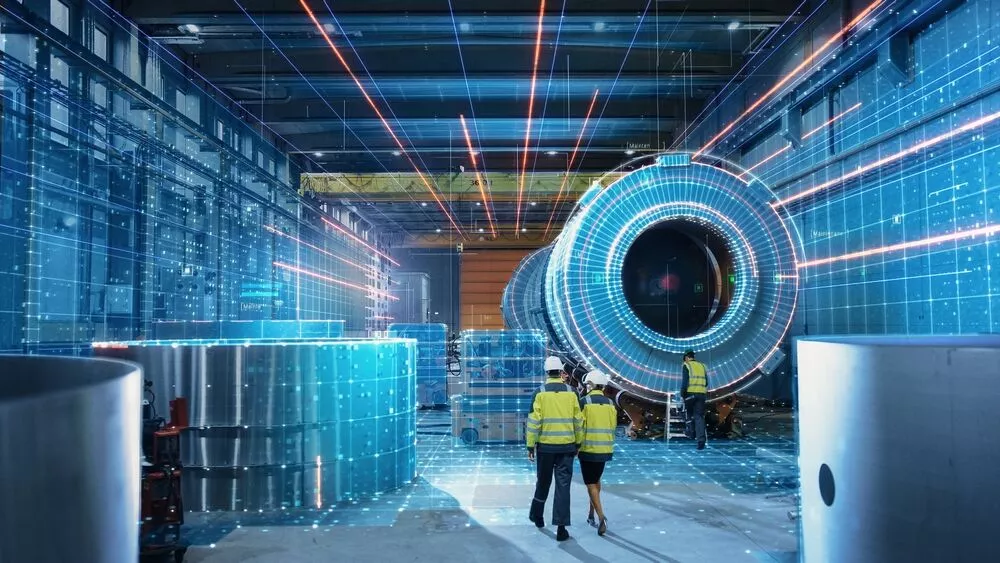

In an increasingly competitive business environment, digital simulation has become an essential tool to optimize projects across multiple sectors. From engineering to production management, simulations allow the creation of precise virtual models to predict outcomes, adjust processes, and make informed decisions. Here are 11 key factors to optimize your projects using digital simulation and maximize the efficiency and effectiveness of your processes.

1. Clear Definition of Objectives

The first step in implementing effective digital simulation is to establish clear and measurable goals from the start of the project. Having defined objectives allows simulations to focus on key areas and directs optimization efforts toward tangible results. Whether it’s reducing costs, improving delivery times, or increasing operational efficiency, having a clear goal facilitates strategic decision-making.

2. Accurate Data Collection

The foundation of any effective digital simulation is the quality of the data. The detailed collection of information about current processes is crucial to creating a simulation model that accurately reflects reality. This includes factors such as production times, operational costs, product variability, and other relevant factors that affect system performance. The more accurate the data model, the more reliable the simulation results will be.

3. System Modeling

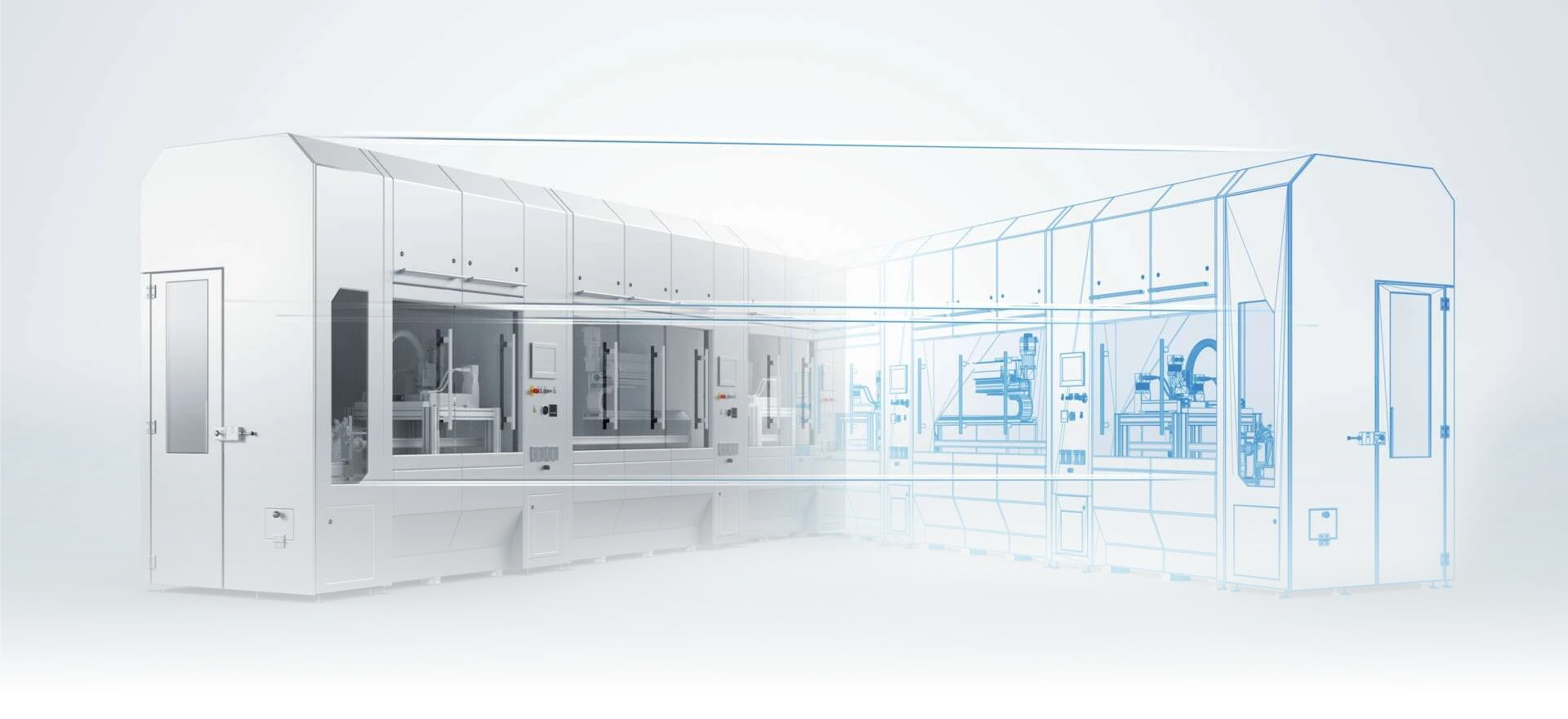

The next step is to create a digital model that accurately represents the system or process to be simulated. This model should reflect all relevant aspects, from operational processes to external variables that may influence system performance. With digital twins and tools like BIM, companies can create extremely detailed and accurate models representing both physical infrastructure and operational processes.

4. Use of Specialized Software

To perform advanced simulations, it is necessary to have specialized software. Platforms like Simul8, AnyLogic, or tools integrated with BIM allow the execution of complex analyses and provide clear visualization of simulation results. These programs offer a visual interface that simplifies data interpretation and strategic decision-making.

5. Rapid Iterations

One of the main advantages of digital simulation is the ability to perform multiple iterations in a short period. This allows for quick adjustments to parameters and evaluation of different scenarios without the cost or risk of making physical changes to the processes. Real-time simulation enables a continuous improvement cycle that is not possible with traditional approaches.

6. Parametric Optimization

Parametric optimization allows for modifying specific parameters of the design or process, such as dimensions, production speed, or material properties, to improve overall system performance. By using digital simulation, different parameter combinations can be tested to find the most efficient and cost-effective one, which is crucial for process optimization.

7. Results Analysis

Analyzing simulation results is a fundamental part of the process. Evaluating the simulations helps identify areas for improvement, assess the impact of different scenarios, and make adjustments to the design or process. This facilitates informed decision-making and the selection of the best strategies to optimize the project.

8. Model Validation

To ensure the reliability of the simulated model, it is important to validate that the simulation results match the real system data. Comparing simulation results with historical data or physical tests ensures the model is accurate and trustworthy, which increases confidence in decisions based on these models.

9. Integration with Optimization Algorithms

Digital simulation can be even more powerful when integrated with optimization algorithms, such as genetic algorithms or heuristic search methods. Digital simulation can be even more powerful when integrated with optimization algorithms, such as genetic algorithms or heuristic search methods. The combination of digital simulation with optimization allows for the discovery of solutions that would not be easily visible through traditional methods.

10. Ongoing Team Training

The success of digital simulation also depends on the continuous training of the teams involved. Training staff in new technologies and digital simulation tools not only improves the quality of work but also strengthens the ability to respond to challenges. Adopting digital simulation requires specific technical skills that need to be developed through continuous training and learning.

11. Cost and Benefit Evaluation

Each iteration and adjustment proposed in the digital simulation should undergo a cost and benefit evaluation. This analysis ensures that the implemented improvements are cost-effective and justify the investment made. Evaluating the return on investment (ROI) for each change made in the process ensures that the project is not only optimized but also stays within the established budget and timeline.

Conclusion

The implementation of digital simulation and project optimization using advanced tools like digital twins, BIM, and parametric simulation offers significant opportunities to improve efficiency, reduce costs, and make more informed decisions. By applying these 11 keys, companies can maximize the performance of their projects and stay competitive in a constantly changing market.

At Foundtech, we offer digital simulation solutions designed to help you optimize your projects and achieve outstanding results. ¿Estás listo para llevar tus proyectos al siguiente nivel? Contact us and discover how our advanced tools can transform your decision-making and optimization process!

JOIN THE NEW REALITY!