Digital Twin vs. Traditional Models.

When to Make the Leap to Real Predictive Maintenance.

Imagine that your plant has been applying predictive preventive maintenance for months: scheduled inspections, analysis of historical data, and statistical models that promise to anticipate failures. Everything seems under control… until a critical line stops without warning,,generating losses of thousands of euros per hour.

Does that sound familiar?

The difference betweenpredicting and truly preventing liesin howyou interpret the data..

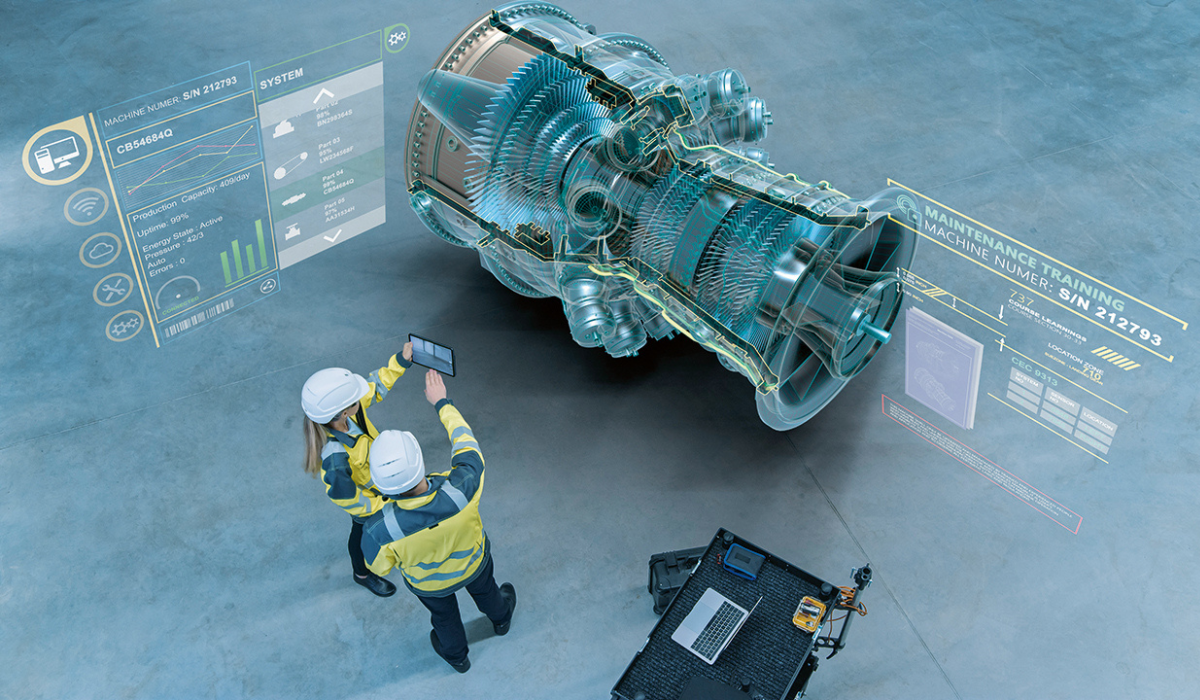

While traditional models work with snapshots of the past, the digital twin creates a living replica of your assets that simulates, learns, and anticipates in real time.

It is not just an evolution of the quality control tools you already know:

it is a paradigm shift in industrial management. .

At Foundtech we have supported dozens of companies in this transition, and the question is always the same:

Is it worth abandoning systems that “work”?

The answer is not black or white. It depends on your operating context, digital maturity, and strategic objectives.

In this article, we break down digital twin vs. traditional models without unnecessary jargon::

what each approach offers, when it makes sense to migrate, and how current tools can coexist with—or be enhanced by—digital twins.

What Is Real Predictive Maintenance?

Beyond Conventional Definitions.

TheTraditional predictive maintenance is based on three main pillars:

- Historical data.

Records of previous failures and estimated component lifespan - Statistical analysis.

Probabilistic models. - Point-in-time sensors

Measurements of vibration, temperature, or pressure at specific moments.

This approach works… up to a point..

It fails when it faces:

- Variable operating conditions (load, climate, shifts).

- Complex interactions between MEP systems.

- Unprecedented events with no historical records.

- Lack of spatial context (location, flows, dependencies).

The structural limitation: static models in dynamic environments.

Traditional quality control tools (CMMS, SCADA, ERP):

- Record data.

- Generate alerts.

- Execute predefined rules.

Butthey do not understand spatial or causal relationships in real time.

Typical example:

- A sensor detects overheating in a motor.

- The system schedules maintenance.

- But it does not know that this motor feeds three critical lines or that there is an undocumented bypass route.

This is where the digital twin makes the difference:

it not only predicts, it simulates complete scenarios before they occur..

Digital Twin: The Living Replica of Your Assets.

A digital twin is not a decorative 3D model. Es una It is a dynamic virtual that integrates geometry, data, and real-world behavior.

Key technical comparison.

Aspect | Traditional Models. | Digital Twin. |

Data | Historical | Real time (IoT) |

Geometry | 2D drawings / CAD | Millimetric scan-to-BIM. |

Simulation | Static snapshot | Predictive and prescriptive |

Integration | Isolated systems | BIM + IoT + IA |

Updating | Manual | Continuous. |

Scope | Component | Entire system |

How a digital twin operates in maintenance.

- Base capture.

3D laser scanning that generates an exact as-built model. - Sensorization.

IoT feeds real-time operational data. - Simulation engine.

AI correlates spatial, environmental, and operational variables. - Predictive scenarios.

“What happens if this compressor fails on the night shift during summer?” - Prescription

It recommends the optimal action, not just triggers alerts.

Real application cases.

- Manufacturing::reduced unplanned downtime by detecting structural, not just mechanical, failures.

- Hospitals: : preventive redistribution of HVAC load before critical thermal peaks.

- Logistics:extended forklift lifespan by correlating real trajectories with wear.

Traditional Quality Management Tools.

What they do well… and where they fall short.

Strengths.

- Mature and standardized processes.

- Lower initial investment.

- Regulatory compliance (ISO 9001, ISO 55000).

- Direct ERP integration.

Key limitations.

- Reactivity: they act after the symptom.

- Information in silos.

- Lack of spatial context.

- Generic models not adapted to physical reality.

When are they still enough?

- Simple, independent assets.

- Operations with low variability.

- Organizations in an early stage of digital maturity.

- Basic regulatory requirements.

Important:

The fact that they are enough today does not mean they will be tomorrow.. We recommend reading: What Is a Digital Twin and Why Your Building Needs One in 2026.

Digital Twin, Sustainability, and ESG.

Unlike traditional models, the digital twin allows you to:

- Predictive energy simulation.

- Real-time optimization.

- Automated and verifiable ESG reporting.

- Regulatory compliance based on real data, not estimates.

Here, operational efficiency becomes a competitive and reputational advantage..

Conclusion: The Real Leap Is Not Technological, It Is Strategic.

The digital twin vs. traditional models debate is not about tools,but about leveof control.

Traditional models help you react better..

Digital twins allow you to decide earlier.

In an environment where:

- Downtime costs millions.

- Energy is increasingly expensive.

- Sustainability is no longer optional.

the difference between maintaining what “works” and evolving toward real predictive maintenance defines which companies will be resilient and which will merely survive.

At Foundtechwe do not believe in technology for technology’s sake We believe in capturing reality with millimetric precision to turn it into operational intelligence that reduces risks, optimizes resources, and builds a more sustainable future.

If your operation can no longer afford reactive decisions, the moment to make the leap is now.. Schedule a diagnostic with us.