BIM Technology in Logistics Centers: How to Optimize Remodeling and Resources with Digital Twins

BIM Technology in Logistics Centers: How to Optimize Remodeling and Resources with Digital Twins

The management of remodeling in operational shopping malls and logistics centers represents one of the biggest challenges in the industry. How can operational continuity be maintained while executing complex structural transformations? The answer lies in BIM technology and digital twins, tools that are redefining project planning and execution in high-rotation spaces.

According to recent industry data, remodeling planned with BIM methodology reduces cost overruns by an average of 18–25% and shortens execution times by up to 30%. This digital transformation not only optimizes resources but minimizes operational interruptions critical to the business.

What is BIM Technology and How Does It Transform Project Management?

In logistics and retail centers, this technology enables:

– Comprehensive visualization: Detailed 3D modeling of facilities, MEP systems, and operational flows

– Scenario simulation: Predicting impacts during active remodels

– Multidisciplinary coordination: Integration of architecture, structure, installations, and logistics

–Asset management: Updated digital inventory of equipment, systems, and spaces

The implementation of BIM transforms reactive projects into predictive processes, where each decision is based on accurate data and validated simulations.

Read also: Discover how digital twins are revolutionizing the construction industry with real success stories.

Resource Optimization Using BIM Methodology

The optimization of resources with BIM is based on the ability to quantify, schedule, and coordinate all project elements before physical execution. This preventive approach generates significant savings across multiple dimensions.

Smart Material Management

BIM modeling allows calculating exact material quantities, eliminating waste due to overestimation and delays due to shortages. Integrated systems generate:

– Automatic material lists (BOQ) updated in real time

– Delivery scheduling synchronized with construction phases

– Identification of reusable materials in remodels

– Optimization of supply routes within the logistics center

Team and Schedule Coordination

The 4D dimension of BIM integrates the time variable, enabling:

- Optimized sequencing: Logical order of activities minimizing interferences

- Efficient allocation of human resources: Team distribution based on space availability

- Identification of critical paths: Focusing resources on determining activities

- Scenario simulation: Evaluation of alternatives before implementation

Real-Time Cost Control

The integration of economic information (5D) facilitates:

– Continuous budget tracking by item

– Automatic alerts in case of deviations

– Integrated earned value analysis (EVA)

– Updated financial projections

Benefits of BIM in Logistics Centers and Retail

Logistics centers and retail present unique characteristics that make the implementation of BIM especially valuable: continuous operation, complex flows, critical systems, and the need for constant adaptability.

Operational Continuity During Remodels

The main benefit of BIM in these spaces is the ability to keep operations running during transformations:

Flow simulation: Modeling of goods and personnel routes during works

Smart phasing: Sequencing that preserves critical operational areas

Logistics coordination: Integration of construction schedules with commercial operations

Access management: Optimization of entry and exit for suppliers and customers

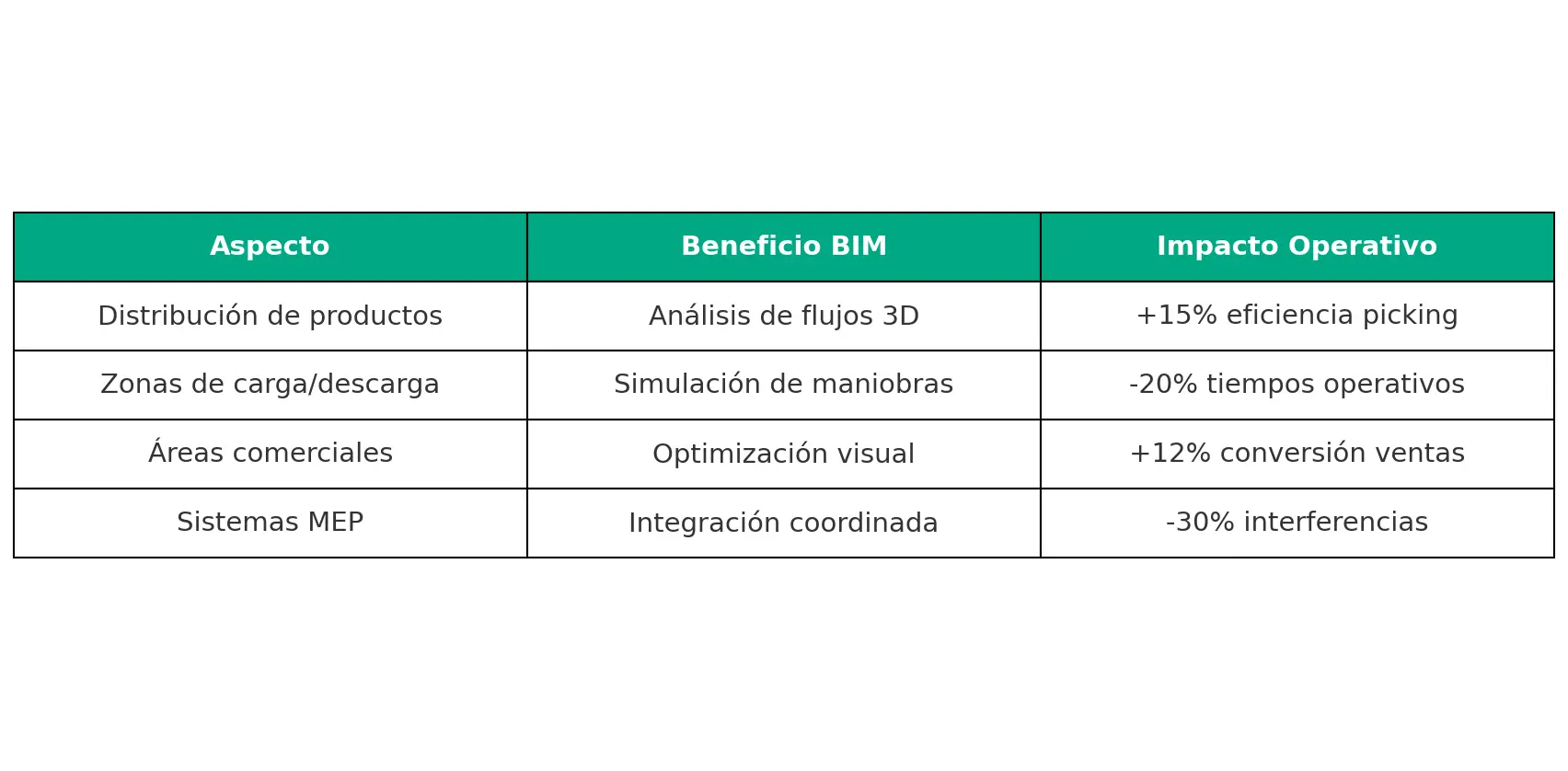

Space and Layout Optimization

BIM facilitates the intelligent reconfiguration of commercial and logistics spaces:

Predictive Maintenance and Asset Management

The digital infrastructure created with BIM becomes the basis for:

Digital inventory of equipment and systems

Preventive maintenance scheduling

Immediate location of installations

Full history of interventions

Integration with IoT systems and sensors

Read also: Explore how BIM-based predictive maintenance is transforming facility management.

Remodeling Planning Processes with BIM

Remodeling planning with BIM follows a structured methodology that maximizes efficiency and minimizes risks. This process develops in clearly defined phases, each with specific objectives and concrete deliverables.

Phase 1: As-Built Survey and Modeling

The process begins with capturing the existing reality:

- 3D laser scanning: Precise capture of geometries and spaces

- Installation survey: Documentation of hidden MEP systems

- Asset inventory: Cataloging equipment and furniture

- Digital modeling: Creation of the as-built digital twin

This phase establishes the digital baseline upon which all interventions will be planned.

Phase 2: Design and Simulation of Alternatives

With the baseline model established, remodeling scenarios are developed:

Requirements analysis: Definition of operational and commercial needs

Generation of alternatives: Multiple distribution and system proposals

Impact simulation: Evaluation of each alternative in operation

Cost–benefit analysis: Economic projection of each alternative, including potential savings and ROI

Thanks to the predictive capabilities of the digital twin, it is possible to anticipate conflicts, adjust designs at early stages, and avoid costly modifications during construction. This not only accelerates decision-making but increases project safety and profitability.

Conclusion

The combination of BIM technology and digital twins offers logistics centers and retail a tangible competitive advantage: faster remodels, with fewer risks and optimized resource use. Comprehensive visualization, multidisciplinary coordination, and the ability to simulate scenarios before execution make BIM an essential tool for maintaining operational continuity and maximizing ROI.

In a sector where every hour of downtime can mean million-dollar losses, adopting this methodology is not just an improvement but a strategic necessity to compete in the Industry 4.0 era .