Digital Twins and AI: Transforming Industrial Operations

In the industrial sector, the use of digital technologies has been growing at an unprecedented rate. Companies are increasingly turning to digital tools like Digital Twins and Artificial Intelligence (AI) to optimize operations and improve efficiency. Digital Twins and AI are revolutionizing the way industrial operations are conducted and transforming the industry in profound ways.

Digital Twins

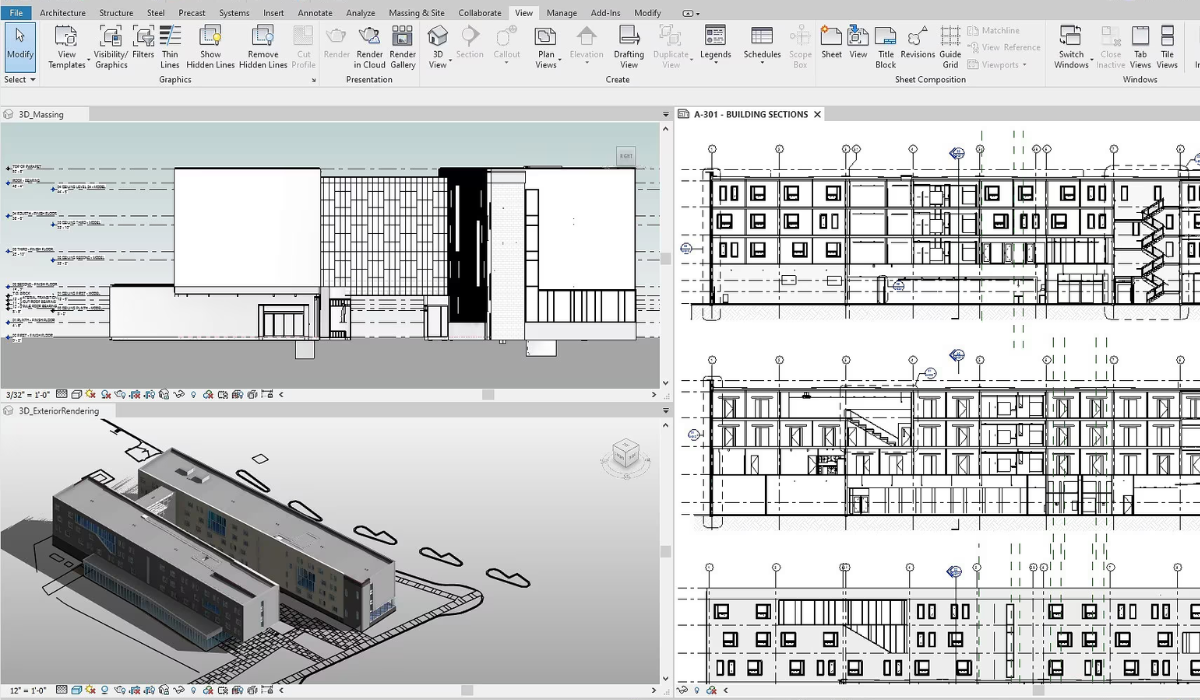

Digital Twins are virtual models of physical assets like machines, processes, and systems. They allow companies to simulate different scenarios and predict outcomes before implementing changes in the real world. Digital Twins can help companies optimize operations, reduce downtime, and improve overall efficiency.

They also enable better collaboration between different teams, leading to more informed decision-making.

AI

AI, on the other hand, refers to the use of algorithms and machine learning to analyze data and make predictions.

AI can be used to detect patterns, identify anomalies, and optimize processes. It can also be used to predict maintenance needs and prevent breakdowns before they occur. AI is particularly useful in situations where large amounts of data are being generated, such as in the industrial sector.

When used together, Digital Twins and AI can be a powerful combination. Digital Twins provide a virtual environment for AI algorithms to work in, allowing them to analyze data and predict outcomes in real-time. This enables companies to make informed decisions quickly, leading to improved efficiency and productivity.

Predict outcomes in real-time

One example of the use of Digital Twins and AI is in the field of predictive maintenance. Predictive maintenance involves using data to predict when maintenance will be needed on a machine or system. Predictive maintenance involves using data to predict when maintenance will be needed on a machine or system.

By predicting maintenance needs in advance, companies can avoid costly downtime and improve overall efficiency. To implement predictive maintenance, companies can create a Digital Twin of a machine or system and use AI algorithms to analyze data from sensors and other sources. The AI algorithms can detect patterns and anomalies that indicate when maintenance will be needed. This information can then be used to schedule maintenance at a time when it will have the least impact on operations.

Another example of the use of Digital Twins and AI is in the optimization of production processes. By creating a Digital Twin of a production process, companies can simulate different scenarios and identify the most efficient way to produce goods. AI algorithms can be used to analyze data from sensors and other sources to identify opportunities for optimization. This can lead to significant improvements in efficiency and productivity.

In conclusion, Digital Twins and AI are transforming industrial operations in profound ways. By providing a virtual environment for AI algorithms to work in, Digital Twins enable companies to analyze data and predict outcomes in real-time. This leads to improved efficiency, productivity, and overall performance. If your company is not already using Digital Twins and AI, it is time to consider implementing these technologies to stay competitive in an increasingly digital world.

At Foundtech, we are committed to helping industrial companies harness the power of Digital Twins and AI to optimize operations and improve efficiency.

Our solution enables companies to easily create Digital Twins and integrate AI algorithms to analyze data and predict outcomes.

Contact us today to learn more about how we can help transform your industrial operations.

Join the new 4.0 digital age!