Digital Twins and Scan to BIM: Revolutionizing Project Planning

The construction industry is undergoing an unprecedented digital transformation. Two emerging technologies are leading this change: Digital Twins and Scan to BIM. Together, they are redefining how projects are planned, executed, and managed, offering unparalleled precision and efficiency.

Integrating these tools not only enhances accuracy in planning and asset management but also boosts collaboration and reduces operational costs. In this article, we explore how the combination of Digital Twins and Scan to BIM is revolutionizing the construction industry and the tangible benefits they bring to project planning.

What Is Digital Twins Technology?

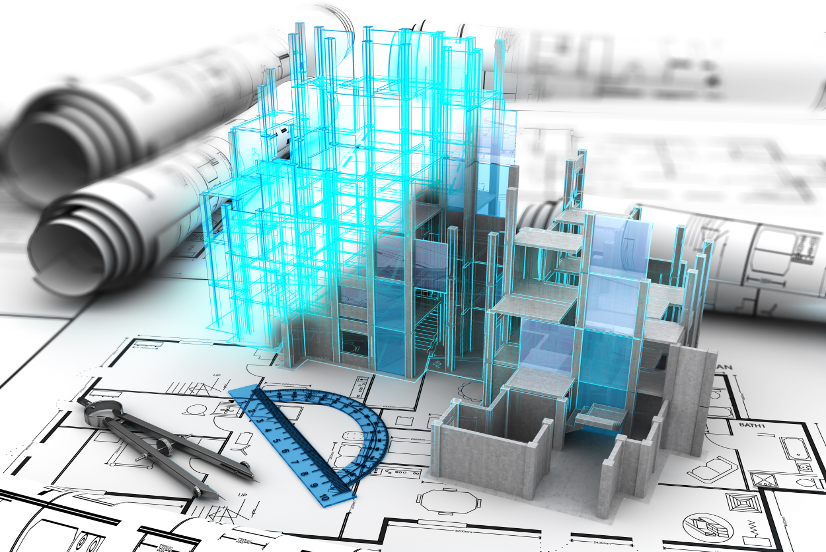

Scan to BIM is a methodology that converts data obtained through 3D laser scanners into detailed digital models. This process begins with capturing the exact geometry of a built environment, generating what is known as point clouds.

MEP Installations Project – Point Cloud. [Gemelos Digitales] | Foundtech®

These point clouds are then transformed into BIM (Building Information Modeling) models, facilitating project planning and execution.

Key Benefits of Scan to BIM

- 🔹 Accurate Data Capture: Provides a reliable foundation for design, minimizing errors from the outset.

- 🔹 Realistic Visualization: Enhances spatial understanding and aids decision-making.

- 🔹 Early Conflict Detection: Identifies potential issues before they become costly construction errors.

- 🔹 Optimized Construction Process: Improves planning and execution, reducing time and costs.

What Are Digital Twins and Why Are They Essential?

A Digital Twin is a virtual representation of a physical asset that simulates its behavior in real time. By integrating data from sensors, IoT (Internet of Things), and other technologies, Digital Twins enable monitoring, analysis, and performance optimization throughout an asset’s lifecycle.

Advantages of Digital Twins

- 🔹 Real-Time Simulation: Predicts problems and optimizes operations before they occur in the physical environment.

- 🔹 Preventive Maintenance: Helps anticipate failures and plan maintenance based on real-time data.

Discover more: What Is Predictive Maintenance and Why Does Your Business Need It?

- 🔹 Enhanced Decision-Making: Facilitates complex data analysis to optimize resources and reduce operational costs.

The Synergy Between Digital Twins and Scan to BIM

The combination of Scan to BIM and Digital Twins creates a powerful platform for comprehensive project management. This integration allows data obtained from 3D scanning to be transformed into accurate digital twins, updated in real time with sensor information and other sources.

How Do These Technologies Complement Each Other?

1️⃣ Accurate Models from the Start: Scan to BIM provides a precise foundation for creating detailed digital twins.

2️⃣ Continuous and Real-Time Monitoring: Digital Twins enable models to be updated with real-time data, ensuring they always reflect the asset’s current state.

3️⃣ Advanced Simulation: The combination allows for simulations that help anticipate issues and optimize project management throughout its lifecycle.

Key Benefits of Integrating Digital Twins and Scan to BIM

1️⃣ Enhanced Accuracy and Precision

The high precision of laser scanning ensures that BIM models accurately represent the built environment. When integrated with Digital Twins, this enables constant monitoring and real-time updates of the asset’s condition.

🔹 Result: Improved conflict detection and reduced construction errors.

2️⃣ Optimized Project Lifecycle

This integration supports efficient project lifecycle management, from initial planning to asset operation and maintenance. With insights from Digital Twins, teams can anticipate problems, schedule maintenance, and extend infrastructure lifespan.

🔹 Benefit: Reduced operational costs and enhanced project sustainability.

3️⃣ Improved Decision-Making Efficiency

The ability to simulate scenarios and evaluate real-time performance allows for faster and more informed decision-making. This is crucial for optimizing resources, adjusting schedules, and minimizing unexpected costs.

🔹 Practical Example: In renovation projects, Digital Twins help assess the feasibility of modifications before physical implementation.

4️⃣ Enhanced Team Collaboration

The integration creates a single source of information accessible to all project stakeholders, from architects and engineers to contractors and owners. This reduces miscommunication and improves team coordination.

🔹 Impact: Fewer project delays and increased operational efficiency.

The Future of Construction with Digital Twins and Scan to BIM

The adoption of these technologies shows no signs of slowing down. With advancements in artificial intelligence and the Internet of Things, the integration of Digital Twins and Scan to BIM will continue to revolutionize the construction industry.

Future Trends:

- 🔹 Augmented reality for visualizing digital twins directly on construction sites.

- 🔹 Advanced predictive simulations to enhance sustainability and reduce the environmental impact of projects.

Conclusion

The integration of Digital Twins and Scan to BIM represents a revolution in project planning and management within the construction industry. Together, these technologies provide unmatched accuracy, improve operational efficiency, and optimize asset management throughout its lifecycle.

If you’re looking to enhance your project planning and leverage the opportunities of digital transformation, Foundtech is here to help.

🚀 Discover how these technologies can transform your next project!