Digital Twins in Logistics: Revolutionizing the Supply Chain with Millimeter Precision

The logistics industry faces unprecedented challenges: supply chain cada vez más complejas, demandas de entregas ultrarrápidaincreasingly complex, demands for ultra-fast deliveries, pressure for sustainability and the need to constantly reduce operational costs.s, presión por la sostenibilidad y la necesidad constante de reducir costos operativos. Mientras que el 73% de las empresas logísticas reportan interrupciones significativas en sus While 73% of logistics companies report significant operational disruptions according to McKinsey Global Institute, a new technology is emerging as the definitive solution: digitaloperaciones según McKinsey Global Institute, una nueva tecnología está emergiendo como la solución definitiva: los digital twins

Los digital twins en logística no son simplemente una representación virtual de tus operaciones; son ecDigital twins in logistics are not simply a virtual representation of your operations; they are intelligent ecosystems that combine real-time data with artificial intelligence and predictive simulationosistemas inteligentes que combinan datos en tiempo real, inteligencia artificial y simulación predictiva to create a mirror version of your supply chain. Esta tecnología permite a empresas como Amazon optimizar sus centros de distribución con una This technology enables companies like Amazon to optimize their distribution centers with 99.7% precision, while DHL has reduced its operational costs by 30% by implementingprecisión del 99.7%, mientras que DHL ha reducido sus costos operativos en un 30% implementando digital twins in their global hubs.

At Foundtech, hemos sido testigos de cómo esta tecnología transforma radicalmente las operaciones logísticawe have been witnesses to how this technology radically transforms logistics operations, from small warehouses to complex multinational distribution networks.s, desde pequeños almacenes hasta complejas redes de distribución multinacionales. Nuestro enfoque en la precisión milimétrica y el mantenimiento predictivo ha permitido a nuestOur approach in millimeter precision and predictive maintenance has enabled our clients to anticipate problems before they occur and optimize every aspect of their supply chain.ros clientes anticipar problemas antes de que ocurran y optimizar cada aspecto de su cadena de suministro.

What are Digital Twins in the Logistics Context?

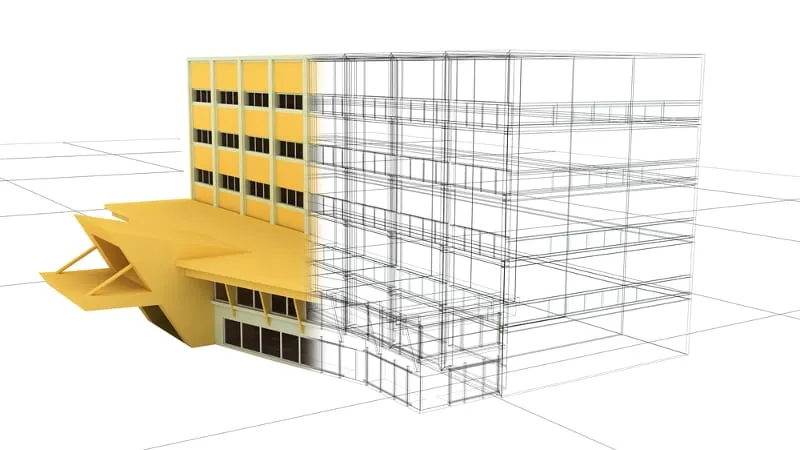

Un gemelo digital logístico es una representación virtual dinámica y en tiempo real de toA digital logistics twin is a dynamic virtual representation in real-time of all components of your supply chaindos los componentes de tu cadena de suministro: from warehouses and distribution centers to transport fleets, inventories and merchandise flows. Esta tecnología va más allá del simple modelado 3D, integrando sensores IoT, sistemas de gestión This technology goes far beyond simple 3D modeling, integrating IoT sensors, warehouse management systems (WMS), GPS data and artificial intelligence algorithms to create a complete predictive ecosystem.de almacenes (WMS), datos de GPS y algoritmos de inteligencia artificial para crear un ecosistema predictivo completo.

Key Components of a Logistics Digital Twin

**Infraestructura Física Digitalizada**: Utilizando tecnologías como el Scan2BIM**Digitalized Physical Infrastructure**: Using technologies like Scan2BIM, an exact representation of logistics facilities is created, including MEP systems (mechanical, electrical and plumbing), warehouse layout and optimized picking routes., se crea una representación exacta de instalaciones logísticas, incluyendo sistemas MEP (mecánicos, eléctricos y de plomería), layout de almacenes y rutas de picking optimizadas.

**Integración IoT y Sensores**: Dispositivos conectados monitorean constantemente temperatura, humedad, ubicación de mercancías, estado de equipos y**IoT Integration and Sensors**: Connected devices continuously monitor temperature, humidity, merchandise location, equipment status and personnel flow, feeding the digital twin with real-time data. flujo de personas, alimentando el gemelo digital con datos en tiempo real.

**Algoritmos Predictivos**: Machine learning e inteligencia artificial analizan patrones históricos y actuales para predecir deman**Predictive Algorithms**: Machine learning and artificial intelligence analyze historical and current patterns to predict demand, identify bottlenecks and optimize distribution routes.da, identificar cuellos de botella y optimizar rutas de distribución.

**Simulación de Escenarios**: Capacidad de modelar diferentes situaciones (picos d**Scenario Simulation**: Ability to model different situations (peak demand, supply interruptions, new routes) without impacting real operations.e demanda, interrupciones de suministro, nuevas rutas) sin impactar las operaciones reales.

Transformative Use Cases in the Supply Chain

Distribution Center Optimization

Digital twins allow simulating and optimizing warehouse layouts before making costly physical changes. These simulations help predict bottlenecks, redesign high-traffic zones and anticipate seasonal demand.

Quantifiable Benefits:

- 15-30% reduction in picking times

- Up to 40% warehouse space optimization

- ROI increase of up to 300% in the first year

85% reduction in inventory errors

IoT sensor integration in transport vehicles with digital twins permite predecir fallas antes de que ocurran.IoT sensor integration in transport vehicles with digital twins This minimizes unscheduled downtime and reduces repair costs by detecting problems before they escalate.

Key Operational Impacts:

- 30-40% reduction in maintenance costs

- 30-40% reduction in maintenance costs

- Increased fleet availability

Reduced impact on time-sensitive deliveries

Intelligent Inventory Management Digital twins allow real-time visualization of inventory levels, analysis of demand patterns, and automation of reorder alerts.

This is especially useful in multi-level and just-in-time operations.

- Competitive Advantages:

- Less overstock with no risk of stockouts

- Dynamic optimization based on seasonality

Predictive consumption analysis

Route and Last-Mile Simulation Route optimization considers real-time traffic, weather conditions, cargo weight, regulations and delivery schedules. This reduces fuel consumption and delivery times.

digital twins help reduce fuel consumption, delivery times and logistics errors.

- Typical Results:

- Reduction of miles traveled: 10-20%

- Improved customer satisfaction scores

Reduced emissions through route efficiency

Faster implementation of process improvements

Converging Technologies: IoT, AI, and Blockchain

The future of supply chain management combines several breakthrough technologies Sensors are the physical foundation of digital twins.

They capture every data point necessary for real-time visibility and predictive analytics.

Artificial Intelligence: Autonomous Decisions Machine learning models make recommendations and even autonomous decisions without human intervention.

From automatic inventory replenishment to dynamic route reassignment, AI is key to future logistics efficiency.

Blockchain: Transparency and Security

1. Autonomous Digital Twins

A secure, immutable record of all supply chain transactions using blockchain.

This enables traceability and prevents fraud.

Integration of mobile robots (AMRs), drones for inventory and autonomous vehicles synchronized with digital twins in real-time.

2. Real-Time Execution with Autonomous Systems

Visualization of warehouses and routes using augmented and virtual reality to improve capacity, space planning and risk detection.

Digital twins represent an unprecedented transformation in supply chain management. By combining IoT, artificial intelligence, and blockchain, they offer companies a clear competitive advantage.

The companies that adopt this technology today will be the logistics leaders of tomorrow. Are you ready to transform your supply chain?

Implementation of interconnected digital twins across the entire logistics chain (warehouse → transport → customer) for a 360° vision.

Conclusion: Digital Twins as the Foundation of Intelligent Logistics The future of logistics is digital, intelligent, and predictive. Digital twins are not just a technology; they are a comprehensive strategy to transform how companies operate their supply chains. It is no longer optional, it is strategic. Companies that embrace digital twins today will dominate their markets tomorrow, while those that delay will risk being left behind in an increasingly competitive logistics landscape.

At Foundtech, we combine experience in BIM, 3D scanning, and artificial intelligence and advanced sensorization to deliver logistics solutions that generate real results. Whether it’s optimizing distribution centers, improving fleet maintenance, or digitizing the entire supply chain, our comprehensive approach is designed to maximize your ROI from month one.

Ready to take your logistics operation to the next level?

Contact us.