Digital Twins in Metallurgical Plants: Optimization and Reduction of Downtime

Imagine a metallurgical plant that detects failures before they occur, adjusts processes in real time, and reduces downtime by up to 40%? That is the tangible promise of digital twins in industry, a key technology of Industry 4.0 that is revolutionizing operational efficiency in the metallurgical sector.

In an environment where even the smallest deviation in production can generate million-dollar losses, the implementation of digital twins becomes a strategic differentiator. Leading companies that are already adopting these solutions are optimizing maintenance, reducing costs, and maximizing the useful life of their assets.

What is a Digital Twin and why is it key in Metallurgy?

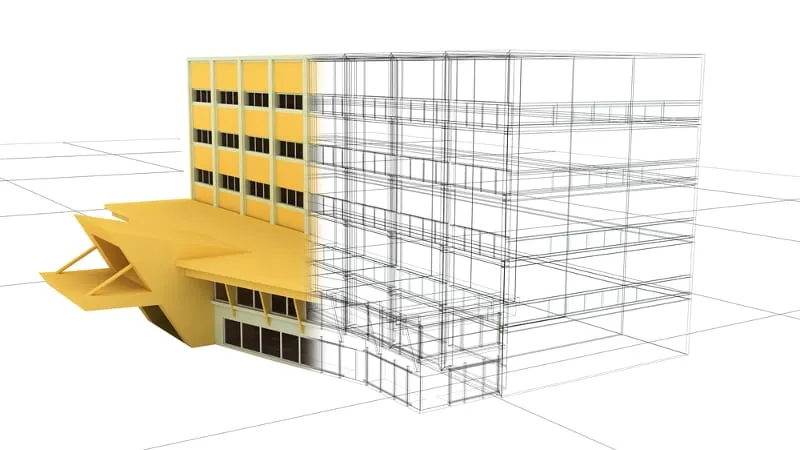

A digital twin is a virtual representation of a physical asset—whether a machine, production line, or even an entire plant—that is updated in real time with data from sensors, SCADA, ERP, and other sources. It is not just a 3D model, but a living tool that simulates, analyzes, and predicts behaviors.

In the case of a metallurgical plant, where the production chain includes furnaces, converters, mills, and critical material transport systems, an unforeseen failure can represent millions in losses. This is where industrial digital twins come in: they allow you to understand every variable in the system, identify bottlenecks, prevent unplanned shutdowns, and optimize the entire production process.

Read also: Digital Twins for Industrial Plants: Strategic Use Cases

Types of Digital Twins and Their Application in Metallurgy

The implementation of digital twins is not monolithic. There are different levels depending on the type of analysis required:

1. Component Digital Twin

It represents a single element, such as a temperature sensor, a motor, or a critical bearing in a mill.

Application in metallurgy:

Real-time monitoring of temperatures in foundry furnaces.

Vibration analysis of conveyor belt motors.

Early detection of wear or overload.

2. Asset Digital Twin

It includes the complete set of components that form an asset such as a furnace, a turbine, or a ventilation system.

Key benefit:

Prediction of structural failures.

Optimization of maintenance cycles.

Simulation of energy efficiency per asset.

3. System Digital Twin

It groups several interconnected assets, such as a complete production line.

Impact on metallurgical plant:

Simulation of material flows.

Analysis of bottlenecks and cycle times.

Management of scheduled shutdowns with minimal interruption.

4. Process Digital Twin

It integrates all systems into a continuous workflow, from raw material input to finished product output.

Strategic advantages:

Real-time analysis of the casting or refining process.

Overall optimization of energy efficiency.

Complete traceability of the production cycle.

Foundtech, as a specialized consulting firm in digital twins, offers comprehensive solutions to implement each type of twin according to the operational needs of each industrial client.

Reduction of Downtime: How Do Digital Twins Achieve This?

According to recent studies, companies implementing digital twins in industrial plants achieve reductions of up to 40% in unplanned downtime.

Strategies that make this possible:

Automated Predictive Maintenance

The digital twin anticipates failures before they occur.

Maintenance alerts are generated based on real conditions, not fixed schedules.

Root Cause Analysis

After a failure, the system generates simulations to understand exactly what caused it.

This allows the root cause to be eliminated and prevents its recurrence.

Simulation of Operational Scenarios

Before stopping the line for maintenance, various scenarios are simulated to choose the one with the least impact.

It also allows testing reconfigurations of the production process.

3D Visualization of Assets and Critical Routes

Facilitates the exact location of critical components.

Improves decision-making by plant managers.

Comprehensive Optimization of Metallurgical Plants

The use of industrial BIM and digital twins in metallurgical plants impacts all operational levels:

Energy Management

Visualization of consumption by asset or area.

Simulation of thermal efficiency of furnaces.

Optimization of industrial ventilation and air conditioning.

Production Planning

Dynamic adjustment of production rate according to real asset availability.

Simulation of different raw material batches to plan the best use of resources.

Industrial Safety

Real-time monitoring of hazardous conditions.

Simulation of evacuations or emergency scenarios.

Staff training with augmented reality integrated into the twin.

Success Cases and Impact Metrics

Global metallurgical sector companies have documented concrete benefits after implementing digital twins:

| Indicator | Average Improvement |

|---|---|

| Downtime Reduction | 35-40% |

| Improvement in Energy Efficiency | 15-25% |

| Increase in Equipment Lifespan | 20-30% |

| Reduced Maintenance Costs | 30% |

| Reduction of Human Errors | 40% |

Implementation Roadmap with Foundtech

Diagnostic Phase

Review of existing infrastructure.

3D laser scanning for creating accurate BIM models.

Modeling and Sensorization

Construction of the digital twin on platforms like Revit or Navisworks.

Installation of IoT sensors and connection with SCADA and ERP systems.

Predictive Integration

Staff Training.

Integration with AI platforms and predictive maintenance.

Scaling

Periodic system review.

Incorporation of new assets into the digital twin.

Conclusion: Is Your Plant Ready to Operate Without Surprises?

In as competitive and sensitive a sector as metallurgy, where every minute counts, digital twins are not a futuristic trend: they are the tool that separates leaders from laggards.

By implementing solutions like those from Foundtech, metallurgical plants not only avoid failures, but also become centers of efficiency, control and sustainable growth.

¿Quieres conocer cómo aplicar esto en tu planta? Explora más contenidos en nuestro blog especializado y descubre cómo iniciar tu propio gemelo digital industrial.