Optimize Facilities with Digital Factory: Business Revolution

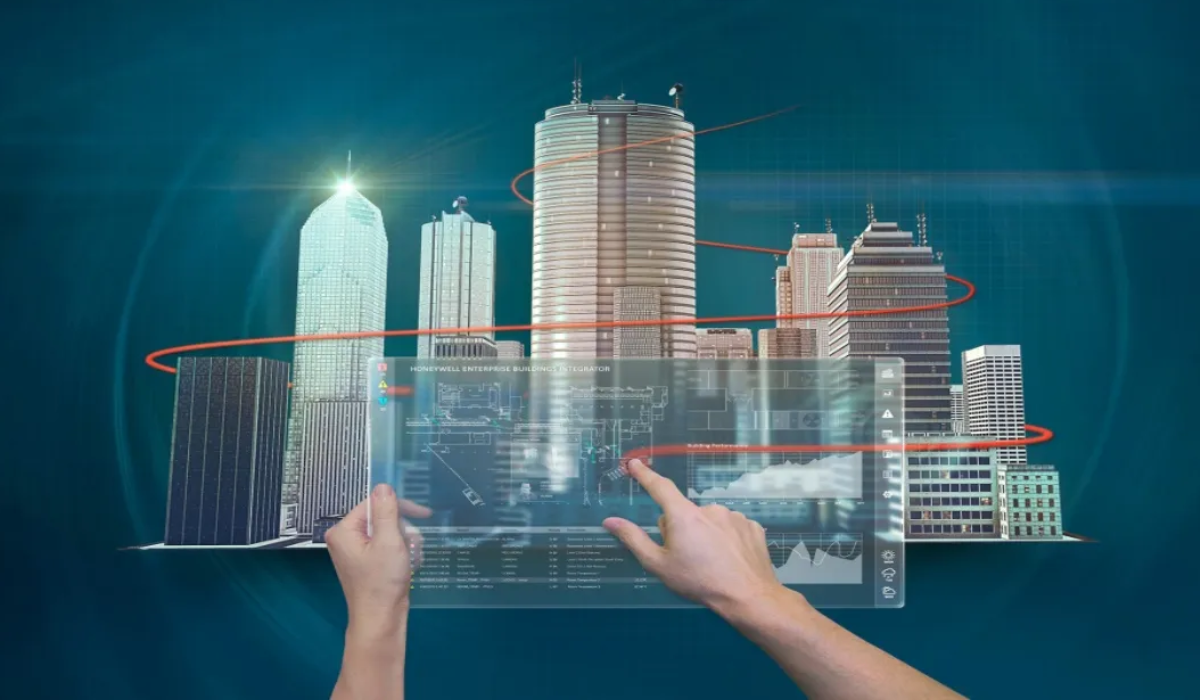

In today’s industrial landscape, where efficiency and innovation are crucial, facility optimization has become a strategic priority for businesses. In this context, the Digital Factory emerges as a revolutionary solution, transforming the way organizations design, manage, and maximize the performance of their factories. At Foundtech, we specialize in implementing this technology to help take your business to the next level.

Below, we explore how the Digital Factory is redefining facility optimization, from the initial design to continuous management, and how it can drive efficiency and profitability in your company.

Visualization of Design: Building the Future Before Starting

One of the most impressive aspects of the Digital Factory is its ability to allow a detailed and precise visualization of the design before construction begins. Imagine having an exact virtual representation of your factory, where you can analyze the layout, machinery distribution, and the location of key equipment.

The Digital Factory is not just about design; it is also a powerful tool for optimizing production processes. Additionally, clear visualization helps communicate the project ideas to all teams, ensuring that everyone is aligned with the strategic goals.

At Foundtech, we use advanced tools like Scan to BIM to ensure that digital models are realistic and rich in detail, facilitating planning and improving decision-making.

Process Optimization: Total Efficiency at Your Fingertips

The Digital Factory is not just about design; it is also a powerful tool for optimizing production processes. Through digital simulations, companies can analyze different work scenarios, evaluate machine configurations, and test production flows before physically implementing them.

This approach allows for:

- Reducing costs associated with subsequent adjustments.

- Increasing productivity by identifying inefficient processes.

- Improving sustainability by minimizing waste.

For example, by simulating the workflow, you can identify bottlenecks in the production line and resolve them before they impact productivity. This level of strategic planning not only improves performance but also reduces the risks of operational disruptions.

Asset Management: Maximizing the Lifecycle of Your Factory

Asset management is another essential component where the Digital Factory demonstrates its value. By integrating real-time monitoring systems and accurate data, this technology allows for continuous tracking of asset status, facilitating maintenance and ensuring optimal operation.

Key benefits include:

- Efficient inventory management: Prevents unnecessary accumulation of spare parts and materials.

- Predictive maintenance: Detects potential failures before they occur, reducing repair costs and downtime.

- Extension of asset lifecycle: Ensures machinery and equipment operate efficiently for a longer time.

At Foundtech, we help companies implement integrated solutions that combine physical data with digital tools, improving asset management and maximizing return on investment.

Planning and Scheduling: Precision in Every Step

One of the most challenging areas in any industrial project is planning and scheduling. This is where the Digital Factory excels, allowing the creation of a digital twin of the physical facility. This model not only facilitates detailed planning but also helps anticipate problems before they occur.

How does it work?

- It generates a virtual replica of the factory to evaluate schedules and workflows.

- It identifies conflicts in planned activities.

- It allows real-time adjustments to avoid delays and maximize productivity.

This ability to predict and solve problems ensures that projects progress without interruptions, keeping both the schedule and budget under control.

Key Benefits of the Digital Factory

Adopting the Digital Factory offers significant advantages for companies seeking to optimize their facilities and processes:

- Realistic visualization: Accurate representation of the project before construction.

- Improved collaboration: Integrates all teams into a unified working environment.

- Design optimization: Detects and solves problems from the early stages.

- Cost reduction: Minimizes costly errors and rework.

- Risk management: Identifies safety and operational risks before they become issues.

- Maximized profitability: Enhances operational efficiency and reduces waste.

Conclusion

The Digital Factory is not just a technological tool; it is a strategic investment that drives efficiency, reduces costs, and improves decision-making in industrial facilities. With Foundtech as your partner, you can maximize the benefits of this technology and take your business to new levels of success and sustainability.

Ready to join the digital revolution? Contact us today and discover how we can help you optimize your facilities and maximize profitability. The future of efficiency is here!

JOIN THE NEW REALITY!