What Is a Digital Twin and How Is It Used in Industrial Plants?

Digital Twins: What They Are, Types, and How They Are Revolutionizing Industry 4.0

Imagine being able to visualize and manage every detail of your industrial plant in a virtual environment that replicates reality with millimetric precision. This is no longer science fiction—digital twins are redefining how industries plan, operate, and maintain their facilities.

At Foundtech, we’ve seen manufacturing, metallurgical, and logistics plants transform their operations with digital twins: from reducing unexpected downtimes by 40% to optimizing production layouts for greater efficiency.

But we understand that taking the first step can be overwhelming. What types of digital twins exist? Which one is best suited for your case? How do you implement it correctly? These are questions our clients ask us regularly.

In this guide, you’ll learn what digital twins are, how they work, and most importantly, how they apply to industrial environments to boost productivity and operational resilience.

What Is a Digital Twin?

What Is a Digital Twin?

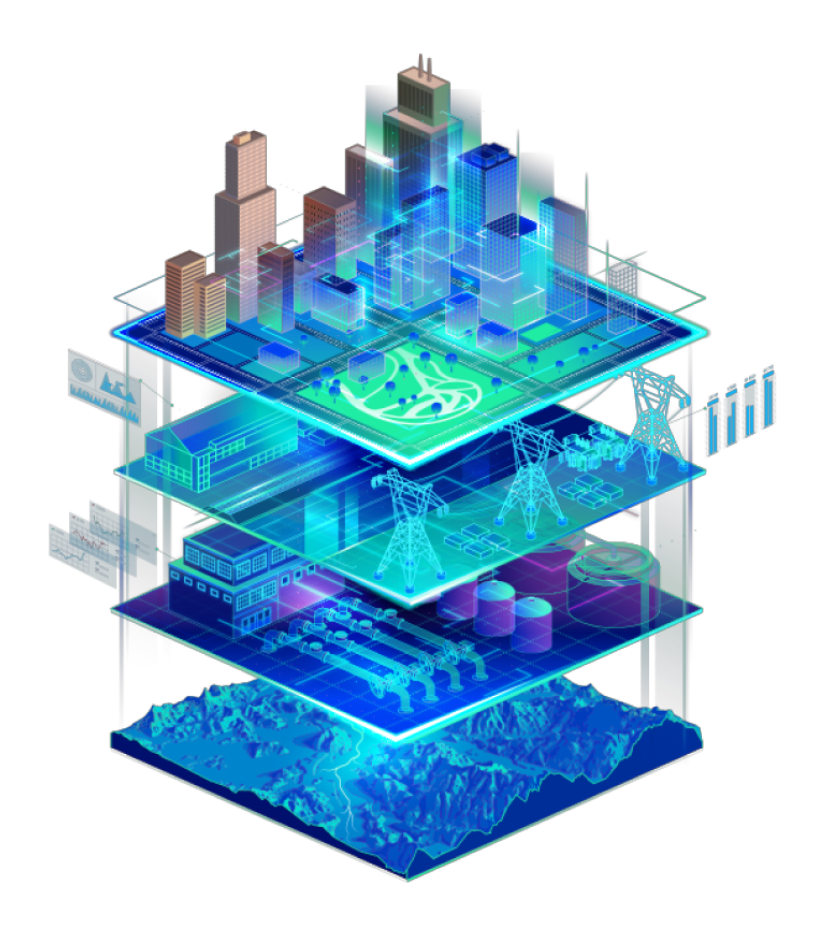

A digital twin is a dynamic virtual representation of a physical asset (such as an industrial plant, machinery, or system) powered by real-time data. This model integrates:

Physical Asset: Plant, production line, equipment, or MEP systems

Digital Model: Interactive 3D replica created with BIM and 3D laser scanning

Data Flow: IoT sensors, SCADA, and management systems that update the twin in real time

The Digital twinning goes beyond a simple 3D model. It incorporates artificial intelligence, predictive analytics, and machine learning to create an interactive experience that constantly evolves with its physical counterpart. The result: a tool that enables scenario simulations, failure prediction, and data-driven strategic decision-making.

According to Gartner, 75% of organizations implementing IoT already use or plan to use digital twins by 2025. This widespread adoption is due to their ability to cut operating costs by up to 30% and improve efficiency by 25%.

Types of Digital Twins for Industry

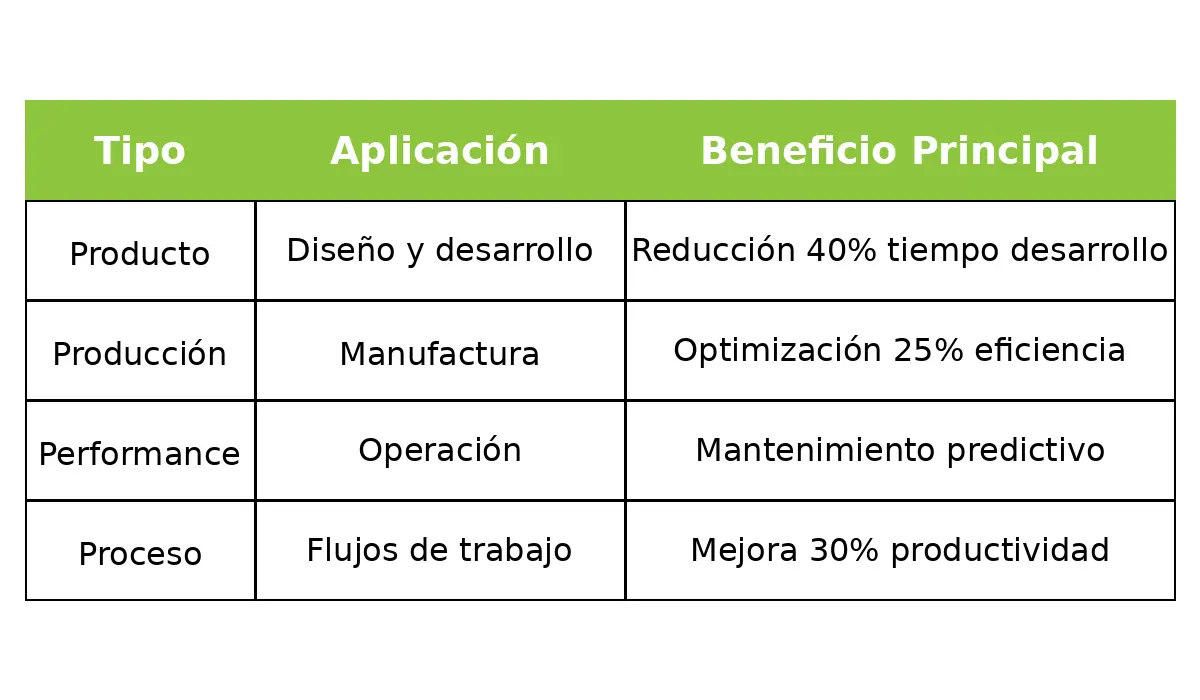

In industrial plants, digital twins can represent different levels of detail:

Component Twin: Focused on specific parts (motors, pumps) Ideal for predictive maintenance

Asset Twin: Covers complete equipment (assembly lines, industrial furnaces)

System Twin: Represents interconnected areas, such as an entire production line

Process Twin: Models operational flows, optimizing internal logistics and layouts

Applications in Industrial Plants

Digital twins offer key advantages across sectors such as manufacturing, metallurgy, logistics, and energy, including:

Predictive Maintenance: Detect anomalies before they cause costly shutdowns

Layout Reconfiguration: Simulate new lines or equipment before moving a single machine

Critical Asset Management: Structural monitoring of roofs, cranes, piping, and electrical systems

Regulatory Compliance: Accurate drawings for NOM, ISO, and civil protection audits

Scenario Simulation: Model risk or expansion situations without disrupting operations

Tangible Benefits for Industry

Reduced Unplanned Downtime: Up to 40% less downtime

Energy Savings: Optimization of HVAC, lighting, and electricity usage

Fast ROI: McKinsey studies estimate returns up to 300% within 3 years

Improved Safety: Early identification of structural and compliance risks

Scalability: Twins adapt to future expansions or new production lines

How to Implement a Digital Twin in Your Plant

3D Laser Scanning (Scan2BIM): Accurate capture of existing infrastructure

BIM Modeling: Construction of the digital model with Levels of Detail (LOD) adapted to your needs

IoT/SCADA Integration: Connection with industrial sensors and control systems

Predictive Analysis: Simulation of maintenance, production, and logistics scenarios

Ongoing Management: Model updates as the plant evolves

At Foundtech, we start each project with a technical assessment to identify areas of immediate impact and design a scalable digitization strategy.

Conclusion

A digital twin in industrial plants doesn’t just replicate your facility—it transforms it into a safer, more efficient, and future-ready operation. From metallurgy to logistics, its implementation accelerates predictive maintenance, improves expansion planning, and reduces costs.

📍 Want to discover how a digital twin could transform your industrial plant?

👉 Request a technical assessment with Foundtech.