3D Scanning and Digital Twins: Driving Efficiency in Industrial Projects

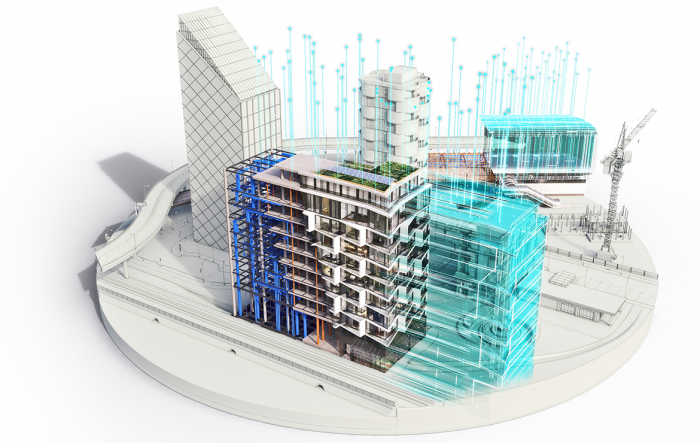

Digital transformation has revolutionized the industrial sector, and the use of 3D scanning along with digital twins is setting new standards for efficiency in industrial projects. These technologies enable the precise capture of data and the creation of virtual replicas of infrastructures and processes, optimizing both the design and operation of projects.

What Are Digital Twins?

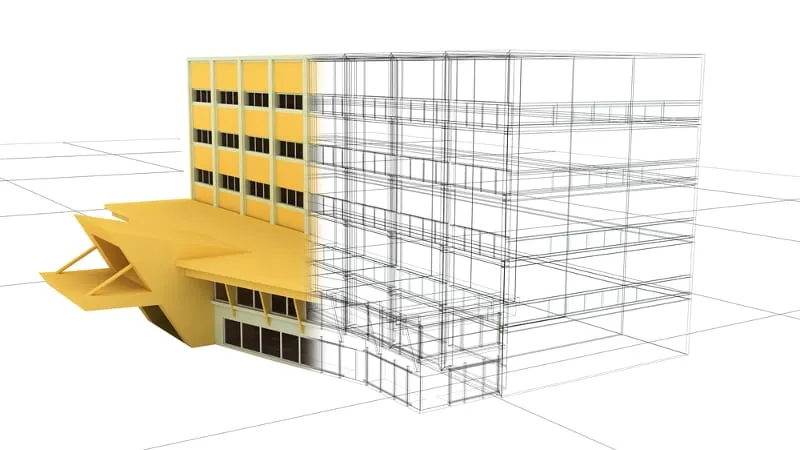

A digital twin is a virtual representation of a physical system that allows companies to simulate and analyze their operations in real time. By integrating data from 3D scanning and other sources, these virtual models provide a detailed view of industrial processes, facilitating informed and proactive decision-making. The use of digital twins in combination with BIM models allows for resource optimization and improved productivity.

ejemplo-gemelos-digitales.webp

What Is 3D Scanning?

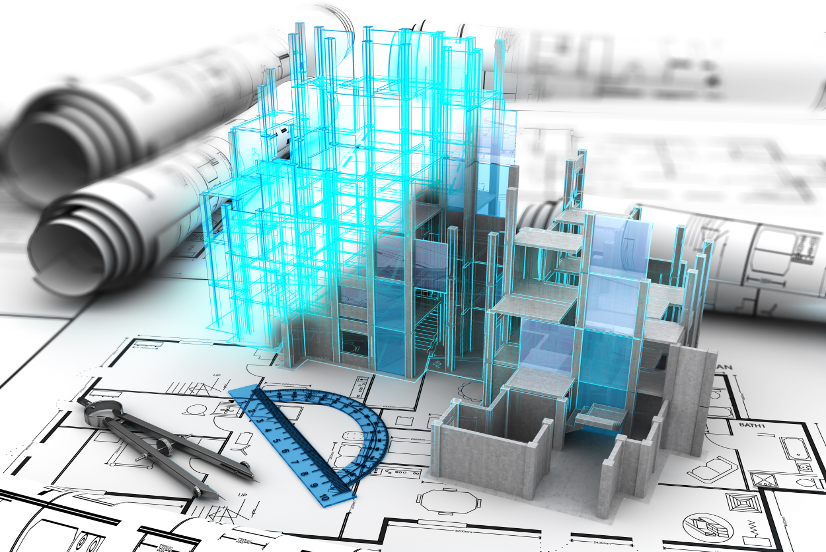

3D scanning is a technique that captures the shape and dimensions of an object or environment in three dimensions using specialized devices. This process generates a digital model that accurately represents the geometry of the scanned object. Below are some key aspects of 3D scanning:

Types of 3D Scanning

Laser Scanning:

Uses a laser to measure distances and create a point cloud representing the object’s surface. It is known for its high precision and is commonly used in industrial and architectural applications.

Photogrammetric Scanning:

Employs photographs taken from different angles to reconstruct a 3D model. This method is useful for large or complex objects and is often used in archaeology, heritage conservation, and landscape modeling.

Contact Scanning:

Involves the use of a device that touches the surface of the object to measure its dimensions. This method is less common but is used in applications where extreme precision is required.

The Synergy Between 3D Scanning and Digital Twins

El uso combinado de escaneo 3D y gemelos digitales maximiza el control y la eficiencia en los proyectos industriales:

Real-Time Monitoring:

With digital twins, it is possible to continuously monitor project conditions, allowing immediate adjustments based on precise data.

Simulation and Process Optimization:

Digital twins enable the simulation of various operational scenarios before making changes. This not only optimizes resource usage but also reduces costs and execution time.

Predictive Maintenance:

Thanks to the detailed information provided by 3D scanning and digital twins, companies can predict and prevent equipment and system failures, enhancing operational continuity.

Advantages of 3D Scanning with Digital Twins in Industrial Projects

3D scanning is essential for precision and efficiency in industrial projects. Through advanced techniques like BIM scanning, companies can capture the exact geometry of infrastructures and create as-built 3D models.

This provides key benefits:

– Precision in Data Capture:

3D scanning allows for capturing millions of points with millimeter-level accuracy, facilitating the creation of BIM models that faithfully represent reality.

– Error Reduction:

By using precise data from the start of the project, design errors are minimized, reducing costly changes during construction.

– Project Acceleration:

The ability to generate as-built 3D models speeds up project delivery time, optimizing planning and execution.

Challenges in Implementation

Despite their benefits, both 3D scanning and digital twins face certain challenges:

– Data Quality:

The accuracy of the models depends on the quality of the data collected.

– Cybersecurity:

The interconnection of systems increases the risk of cyber vulnerabilities, making it crucial to have proper protection measures in place.

Conclusion

The integration of 3D scanning and digital twins is driving a significant transformation in industrial projects. These technologies not only enhance precision and operational efficiency but also foster a safer and more collaborative environment. As digital transformation continues, the use of these tools will be key to improving competitiveness in a constantly evolving sector.

Ready to optimize your next industrial project with 3D scanning and digital twins?

JOIN THE NEW REALITY!