3D Scanning + BIM: The Revolution in Architectural Renovations with Point Clouds

How to Use 3D Scanning and BIM to Remodel: A Complete Guide from As-Built to Digital Twin

Imagine standing in front of a 100-year-old historic building, with outdated plans and the urgent need for a full renovation. This was the challenge faced by the team of architects at the Hotel Majestic—until they discovered the transformative power of 3D scanning combined with BIM..

Creating precise as-built drawings used to be a tedious process of manual measurements and exhaustive documentation. Today, technology has revolutionized this task: using point clouds generated by 3D laser scanners, we can capture every detail of an existing structure with millimetric precision in a matter of hours.

https://www.youtube.com/watch?v=1Z3UXfsx3xw

At Foundtech, we’ve seen how this combination of 3D scanning and BIM modeling is changing the game in renovation planning.. The resulting digital twins not only remove guesswork from the process, they also enable visualization and planning of modifications with unprecedented precision.

But how exactly does this synergy between technologies work, and what’s the best way to leverage it? In this guide, we’ll show you step by step how to implement these tools to transform your renovation projects.

The Complete 3D Scanning Process to Generate As-Built Plans

The Architectural surveying with a 3D laser scanner : follows a structured protocol that ensures complete and accurate capture of spatial information. The process is divided into three fundamental phases

Phase 1: Planning and Data Capture

Strategic planning determines project success. Modern 3D laser scanners can capture up to 2 million points per second with ±1 mm accuracy at 10 meters.

Key capture steps:

– Site reconnaissance and definition of scan stations

– Placement of reference targets for automatic registration

– Systematic capture from multiple positions

– Complementary photographic documentation for texturing

Phase 2: Point Cloud Processing

Once the data is captured, processing converts raw information into a usable model. The Specialized BIM software such as Revit and AutoCAD, or dedicated tools like CloudCompare and ReCap Pro, process files in E57 or RCP formats.

Processing includes:

– Registration and alignment of multiple scans

– Noise cleaning and filtering

– Automatic classification of construction elements

– Generation of architectural sections and floor plans

Phase 3: As-Built Drawing Production

As-built drawings represent the real-world state of construction, including all modifications and deviations from original plans. The 3D laser scan’s precision allows detection of variations as small as 2 mm in structural elements.

Discover our specialized services that can accelerate your as-built documentation project.

Integrating Point Clouds into BIM Models for Renovations

The Effective integration of point clouds into BIM software requires an optimized workflow that preserves accuracy while facilitating 3D modeling.. This process transforms raw geometric data into intelligent parametric models.

Import & Setup in Revit

Revit has become the leading platform for integrating point clouds in renovation projects. Import workflow:

- File preparation: Convert to optimized RCP/RCS format

- Coordinate setup: Establish a common origin point

- Smart segmentation: Split by levels or work zones

- Display configuration: Adjust density and coloring for efficient modeling

Parametric Modeling Over Point Clouds

The Parametric 3D modeling allows you to create BIM elements that automatically adapt to existing conditions. Architects can:

– Generate walls that follow detected irregularities

-Create custom families for unique elements

– Set construction tolerances based on real data

– Integrate facility management information for future maintenance

A McKinsey study found that projects using this methodology reduce construction errors by 40% and accelerate the design phase by 25%.

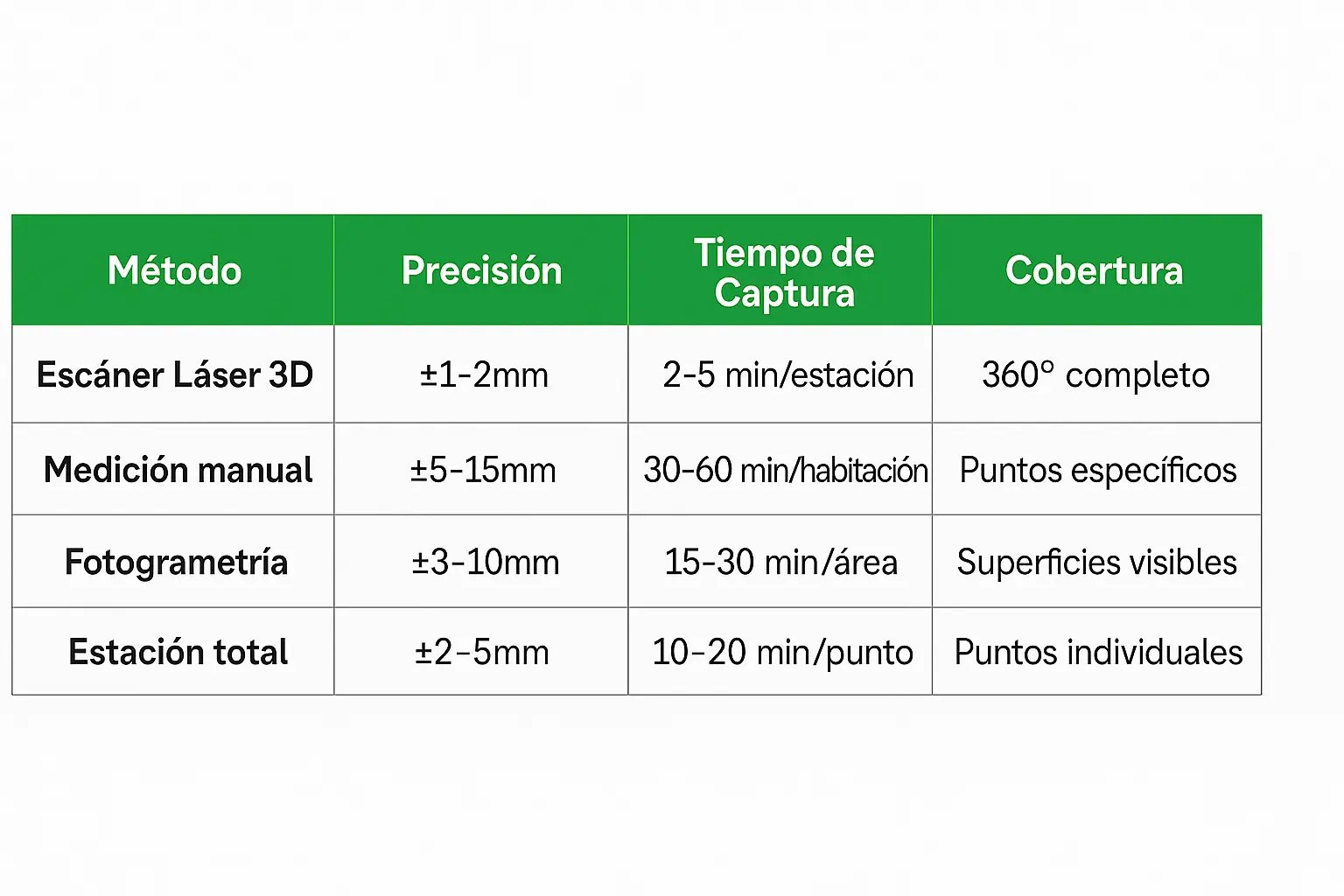

Advantages of 3D Laser Scanning vs. Traditional Measurement Methods

Comparing 3D laser scanning with traditional methods reveals significant differences in accuracy, time, and total project cost.

Quantifiable Benefits of 3D Scanning

Quantifiable Benefits of 3D Scanning

Time reduction: Architectural survey projects that traditionally took weeks can now be completed in days. A 5,000 m² office building can be fully scanned in 6–8 hours.

You might also like: 3D BIM Surveying & Digital Twins: The New Era of Smart Hospital Infrastructure

Improved accuracy: Capturing millions of points eliminates interpolation and estimation, providing an exact representation of existing geometry.

Comprehensive documentation: Every element is recorded, including hidden installations, structural deformations, and complex architectural details.

Fewer site visits: The point cloud enables remote measurements, reducing disruptions in operational buildings.

Workflow: From Capture to BIM Model Delivery

An optimized workflow ensures an efficient transition from data capture to delivery of a fully functional digital twin.

Stage 1: Capture & Documentation

Systematic capture includes:

– High-resolution 3D laser scanning

– HDR photography for realistic texturing

– Documentation of environmental conditions

– Recording of non-visible elements (installations, hidden structures)

Stage 2: Processing & Modeling

The advanced process transforms raw data into usable information:

Data cleaning: Removal of noise and temporary elements

Automatic registration: Precise alignment of multiple scans

Smart classification: Automatic identification of building elements

Parametric modeling: Creation of intelligent BIM elements

Stage 3: Validation & Delivery

Validation ensures the quality of the digital twin:

– Dimensional verification against set tolerances

– Geometric consistency checks

– Validation of metadata and element properties

– Export to standard formats (IFC, DWG, RVT)

Conclusion: Transforming the Future of Renovations

Integrating 3D laser scanning with BIM modeling not only optimizes the as-built documentation process—it ushers in a new era of architectural renovations: more precise, faster, and with a lower margin of error.

Thanks to point cloudsit’s now possible to capture every physical detail of an existing building with millimetric precision, avoiding costly repeat site visits and drastically reducing survey time. When integrated with platforms like Revit, intelligent parametric models are generated that not only allow planning over existing conditions, but also help anticipate problems, coordinate multidisciplinary teams, and simulate scenarios before execution.

This workflow—from scan to BIM model, and from there to the digital twin—enables architects, engineers, and managers to make data-driven decisions, adapt to real-world site conditions, and deliver high-impact renovations with full control over time, cost, and quality.

At Foundtech, we believe this approach isn’t the future—it’s the present. If you’re considering a complex renovation, updating a building without current plans, or simply digitizing your real-estate portfolio, 3D scanning + BIM is the ideal path.

👉 Want to know how to apply this methodology to your next project?

Contact us and let’s talk about your digital twin.