BIM and Laser Scanning: The New Standards for Industrial Projects

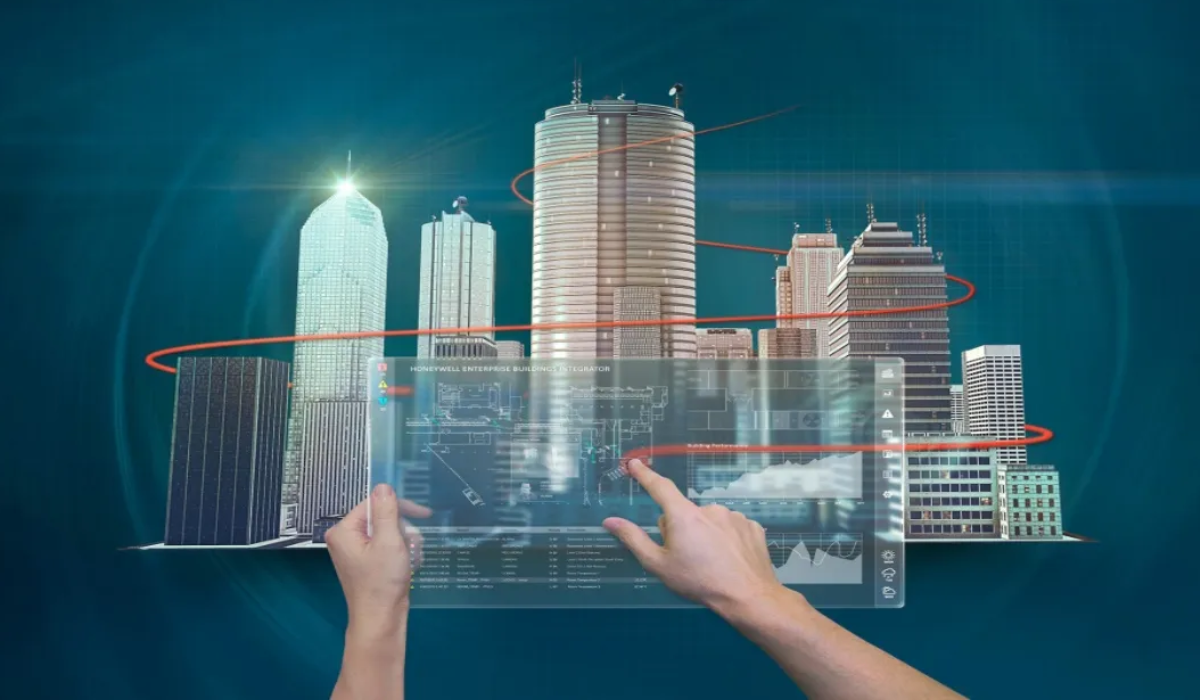

The integration of Building Information Modeling (BIM) and laser scanning is transforming the management of industrial projects. These technologies offer significant improvements in accuracy, efficiency, and collaboration, setting new standards in the sector. In a world where digital transformation is driving industrial progress, the combination of BIM and laser scanning ensures that projects are executed with greater precision and fewer errors.

BIM: A Collaborative Approach

BIM is a digital methodology that facilitates the creation of three-dimensional models of buildings and structures, integrating critical information about the physical and functional aspects of a project. In the industrial sector, BIM enables architects, engineers, and contractors to collaborate more efficiently from the early stages of a project, sharing an up-to-date digital model. This collaboration reduces errors, improves coordination, and optimizes resource use—essential factors in executing large-scale industrial projects.

Laser Scanning: Precision and Detail in Design

Laser scanning is a technology that uses devices like LiDAR to capture three-dimensional data of an environment, generating highly precise point clouds that represent physical reality. These data are crucial for industrial projects as they provide an exact representation of the current state of the site. The precision of laser scanning allows teams to plan and execute projects with a level of detail that was previously difficult to achieve, minimizing costly errors and unnecessary delays.

The Synergy Between BIM and Laser Scanning

The integration of BIM and laser scanning in industrial projects offers several key benefits:

Improved Modeling Accuracy: The data obtained through laser scanning is integrated into BIM models, ensuring that the digital model accurately reflects the real-world conditions of the site. This is essential in industrial projects where precision is critical.

Workflow Optimization: The interoperability between different BIM software platforms and laser scanning data facilitates a more efficient workflow. This enables information to flow seamlessly between the various stakeholders, streamlining the design and construction processes.

Project Lifecycle Management: With a BIM model updated with accurate laser scanning data, companies can better manage the complete lifecycle of the facility. This includes everything from construction to maintenance, allowing for informed decisions based on real-time site conditions.

Applications in Industrial Projects

The integration of BIM and laser scanning has multiple practical applications in the industry, such as:

Construction and Planning: The combination of both technologies significantly improves project planning, enabling a clear visualization of potential clashes or issues before they occur.

Infrastructure Maintenance: BIM models updated with laser scanning data allow for better management of industrial facility maintenance, ensuring that teams work with accurate, real-time information.

You might be interested in: Scan to BIM: A New Frontier in Architectural and Engineering Precision

Conclusion

The integration of BIM and laser scanning is setting new standards in industrial projects. These technologies not only improve the accuracy and efficiency of projects but also foster more effective collaboration between the various stakeholders. As digital transformation continues to drive the evolution of industries, the joint adoption of BIM and laser scanning will be key to addressing the complex challenges of modern industrial projects.

Are you ready to implement BIM and laser scanning in your next industrial project?

JOIN THE NEW REALITY!