Container Management with Digital Twin: Reduce Emissions

How to Reduce Emissions in Logistics with BIM and Digital Twin Technology: The Sustainable Revolution in Ports

The roar of engines, the constant movement of containers, and columns of smoke rising into the sky are everyday scenes in any logistics port. But what if we could radically transform this landscape without sacrificing operational efficiency?

Dock digitalization is no longer a futuristic vision—it’s a transformative reality that is revolutionizing the logistics industry. Container management with a digital twin not only optimizes workflows but also marks a turning point in port sustainability by enabling emission reductions.

At Foundtech, we’ve witnessed how the convergence of BIM technology and digital twins is redefining efficiency and sustainability standards in the logistics sector. Every day, more companies discover that reducing emissions in logistics doesn’t come at the cost of productivity—in fact, it enhances it.

In this article, we’ll explore how these technologies are transforming port logistics, presenting real-world cases and practical strategies that prove a greener, more efficient future isn’t just possible—it’s already here.

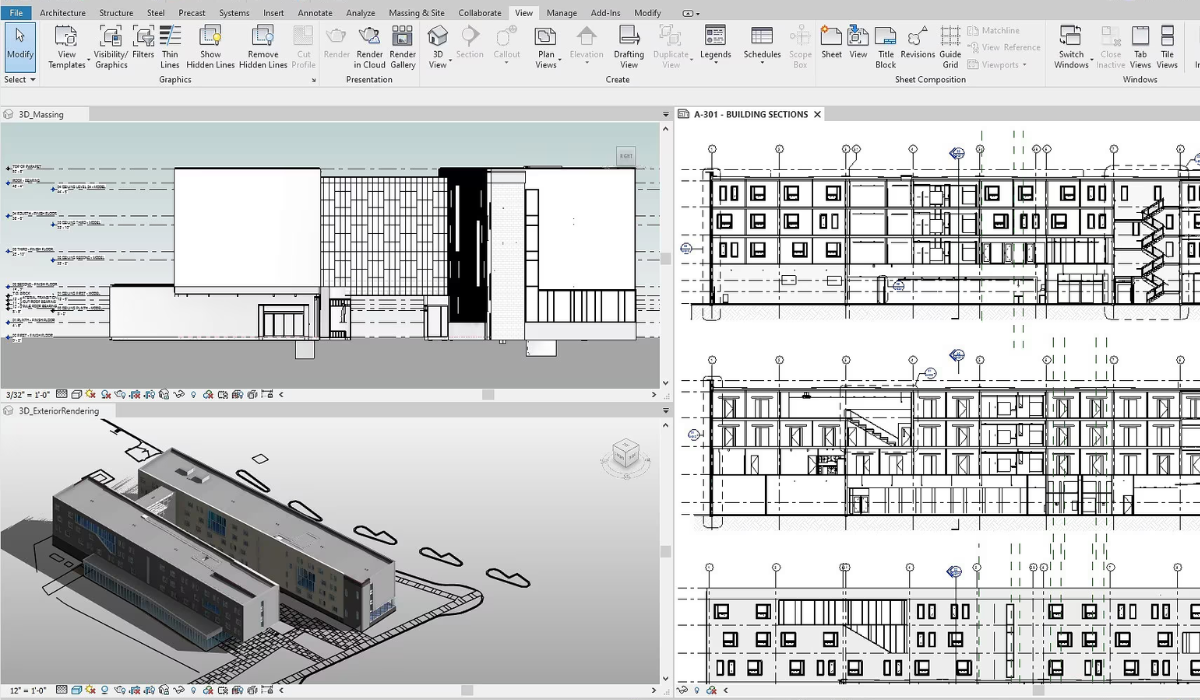

How BIM Reduces Emissions in Logistics: Technological Foundations

Quantifiable BIM Benefits in Logistics (Estimates):

– 20–30% reduction in loading/unloading times

– 15% optimization in internal transport routes

– 25% decrease in energy consumption of equipment

– 40% improvement in preventive maintenance planning

Dock digitalization via BIM enables real-time monitoring of energy consumption in cranes, lighting systems, and handling equipment. This granular visibility is essential to identify optimization opportunities that traditionally went unnoticed.

Digital Twins in Ports: Operational and Environmental Benefits

Digital twins represent the natural evolution of BIM, creating dynamic virtual replicas that are constantly updated with real-time data. In port contexts, a digital twin integrates information from IoT sensors, traffic management systems, weather conditions, and demand patterns.

What are the benefits of a digital twin in ports? The answer lies in its ability to predict, simulate, and optimize complex operations before they occur in the physical world.

Main benefits include

Predictive Optimization:

– 95% accuracy in congestion prediction

– Automated planning of optimal routes

– Proactive management of energy resources

– Predictive maintenance of critical equipment

Emission Reduction:

-Minimized vessel idle time (30% emission reduction)

– Optimized container movements (25% fuel savings

– Smart lighting and climate control management

– Efficient coordination of handling equipment

Container management with a digital twin enables simulation of thousands of operational scenarios in minutes, identifying the optimal configuration that minimizes both operation time and associated emissions.

Dock Digitalization: Enabling Technologies and Implementation

Dock digitalization requires a robust technological architecture that integrates multiple systems and data sources. This transformation goes beyond simple automation, creating intelligent ecosystems that continuously learn and adapt. que aprenden y se adaptan continuamente.

Key Components of Digitalization:

IoT Sensors and Monitoring:

– Air quality and emission sensors

-Real-time energy consumption monitors

– RFID-based container tracking systems

– Weather sensors for operational optimization

Integration Platforms:

– APIs to connect legacy systems

– Middleware for real-time data processing

– Executive dashboards with environmental KPIs

– Automated alert systems Body

Successful Implementation Cases: Emission Reduction via Digitalization

The HVCC (Hamburg Vessel Coordination Center) enables vessel speed optimization before arrival. An estimated fuel saving of over 22 tons—equivalent to about 66 tons of CO₂—was achieved by reducing the speed of an 18,000-TEU vessel from 18 to 14 knots.*

Using Fujitsu’s quantum optimization algorithms (Digital Annealer), the Hamburg Port Authority (HPA) achieved up to a 9% CO₂ emissions reduction and a 15% decrease in vehicle congestion.*

The key to success lies in gradual integration, starting with pilot systems in specific areas before scaling to the entire port operation.

Container Management with Digital Twin: Intelligent Optimization

Container management is one of the biggest operational challenges in ports, where every inefficient move translates to added emissions and operational costs. Digital twins transform this management through optimization algorithms that consider multiple variables simultaneously.

How does BIM improve container efficiency? The answer lies in the ability to model and simulate complex operations before physically executing them.

Optimization Algorithms:

– Optimal stacking plan

– Minimized internal transport routes

– Intelligent loading/unloading sequencing

– Workload balancing

Sustainability and ROI Metrics: Measuring Real Impact

The implementation of BIM and digital twin technology in logistics must be justified with concrete metrics that demonstrate both environmental impact and return on investment. Leading organizations have developed measurement frameworks that integrate environmental and financial indicators.

Key Environmental KPIs:

Emission Reduction:

CO₂ equivalent per TEU processed

– Percentage reduction in total emissions

-Energy efficiency per operation

– Carbon footprint per ton handled

Operational Efficiency:

– Average vessel dwell time

-Equipment and resource utilization

– Productivity per man-hour

– Space utilization rate

Measurement Methodology:

Effective measurement requires setting baselines before implementation and continuous monitoring afterward. Digital twins facilitate this measurement by providing granular, real-time data.

Critical Success Factors:

-Commitment from top management

– Comprehensive staff training

– Gradual and planned integration

– Ongoing results monitoring

-Organizational cultural adaptation

The Future of Sustainable Logistics: Trends and Opportunities

The convergence of BIM, digital twins, and artificial intelligence is shaping the future of port logistics. Emerging trends point to fully autonomous ecosystems that optimize operations in real time while minimizing environmental impact.

Emerging Technologies:

Advanced Artificial Intelligence:

– Machine learning for demand forecasting

– Multi-objective optimization algorithms

– Natural language processing for documentation

– Computer vision for automated inspection

5G Connectivity and Edge Computing:

– Ultra-low latency for real-time control

– Distributed data processing

– Instant machine-to-machine communication

– Augmented reality for operations

Blockchain and Traceability:

– Immutable documentation of operations

– Complete emission traceability

– Smart contracts for automatic optimization

– Digital sustainability certification

Impact Projections 2025–2030:

– 40–50% reduction in port emissions

-Automation of 70% of routine operations

Full integration of supply chains

Carbon-neutral ports as the standard

Adopting these technologies is not optional for organizations seeking to remain competitive in an increasingly sustainability-conscious market.

Conclusion: Transforming Logistics Toward a Sustainable Future Body

Reducing emissions in logistics through BIM and digital twin technology is not just a tech trend—it’s an imperative for competitive survival in today’s market. The data shows that dock digitalization and smart container management can reduce emissions by 25–40% while significantly improving operational efficiency.

Successful implementation requires a holistic approach that combines advanced technology, cultural change, and organizational commitment.

At Foundtech, we understand that every port has unique challenges that require tailored solutions. . Our team of digital twin and BIM experts is ready to guide you through this transformation toward more sustainable and efficient logistics.

Ready to transform your logistics operation? Get in touch with our specialists and discover how we can help you reduce emissions while optimizing productivity. Sustainability and efficiency are not conflicting goals—they are the future of smart logistics.