Digital Twins and their simulation.

According to theory, every change in a business should be oriented towards growth. However, in practice, immediate positive results are not always obtained when modifying our infrastructure or production systems. Thanks to technology, digital twins and their simulation, nowadays we can mitigate these difficulties and make more assertive changes. Do you want to know how to achieve this? Below, we will explain how.

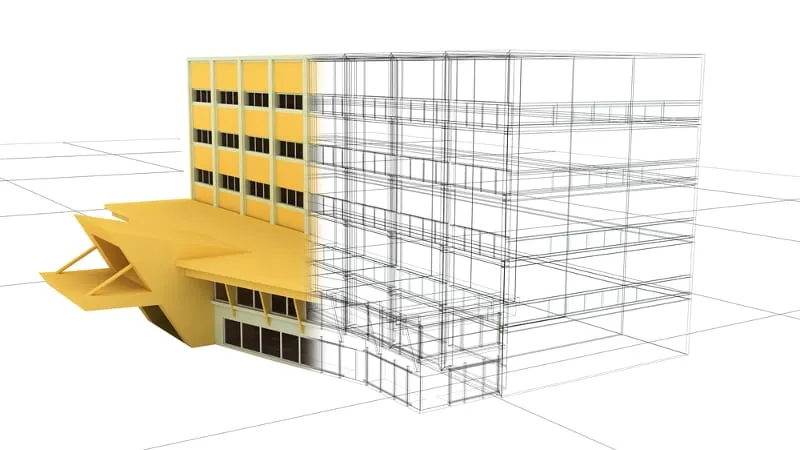

In our previous blogs, you have probably discovered what a digital twin is. In brief summary, it can be said that it is basically a virtual representation of our physical facilities that includes all the spatial, technical, and specialized information in an organized way that guarantees easy and quick access to all the data of our infrastructure. Analyzing this definition and the following example, you will realize the facilities that a digital twin provides for planning changes and/or growth projections for your business.

Imagine that you have a fully automated system in a production line operating 24 hours a day continuously. The system works perfectly, however, due to strategic issues and business growth, it is decided to install a second line of similar or larger size than the first.

How could you know if your current facilities would have the capacity to support another assembly line?

Making these types of modifications to the infrastructure based on trial and error would be too costly, take too much time, and would likely generate downtime in the current production process. A digital twin allows us to create different virtual scenarios for change quickly, economically, and effectively.

- Will we have enough space to install the new machines?

- Where will the new pipes be located to supply their lines?

- What location will be best for installing this new production line?

All of these questions would take a long time to answer without the necessary information. Fortunately, thanks to Foundtech’s high-precision scanning and 3D modeling processes, you can have all the necessary spatial information about your infrastructure in one file with a high degree of reliability.

Watch an example of 3D modeling process

Thanks to the large amount of information included in our digital models, you can simulate and generate, among other things:

- Pipeline routes

- – Equipment placement on site under real conditions

- – Visualizations through virtual reality for staff training without risk

- – Budget planning and stages

- – Generate virtual tours of facilities

- – Updated and reliable architectural and installation plans

- – Volumes and actual areas of different spaces

- – Audit of built or under-construction infrastructure

- – Future growth planning

- – Optimization of workspaces, warehouses, and storage areas

- – Connection with energy efficiency systems and reduction of CO2 impact

- – Centralization of all infrastructure information in an easy-to-share and consult file (plans, technical data sheets, catalogs, quantifications, modifications)

These are just some examples that you can achieve with this new technology; applications are varied depending on specific cases and problems facing your company.

Making strategic decisions to achieve positive changes in our business is now easier by relying on this trending new technology.

JOIN THE NEW REALITY!

Escrito por Sergio Franco - BIM Expert