Digital Twins: The Key to Unlocking the Potential of Industry 4.0

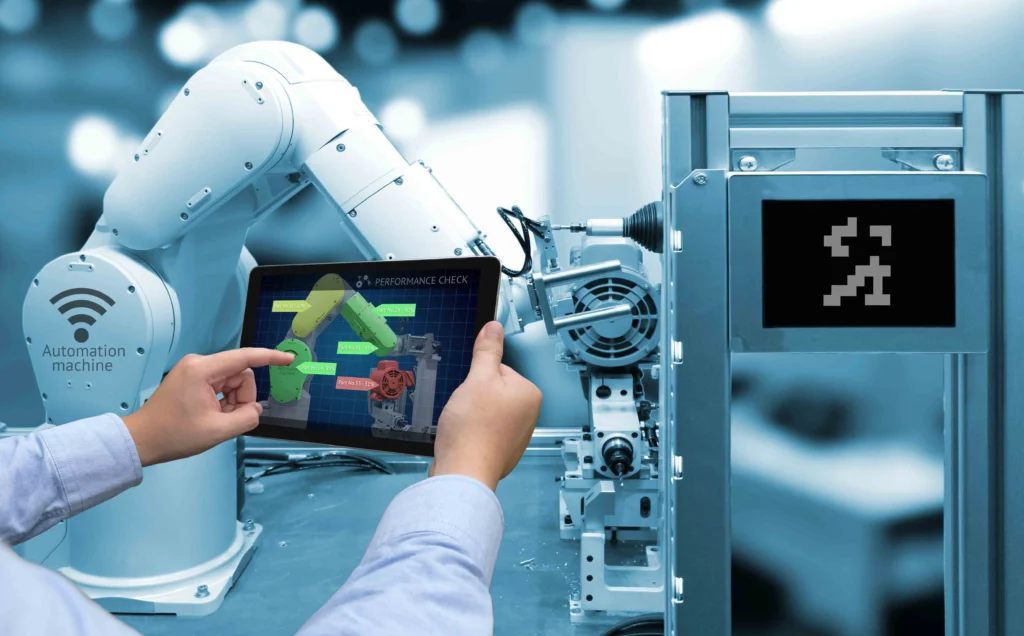

Industry 4.0, characterized by the integration of advanced technologies such as artificial intelligence, the Internet of Things (IoT), and big data, is transforming manufacturing and other sectors. In this context, digital twins emerge as a revolutionary tool that promises to take this transformation to a new level. But what are digital twins, and why are they so crucial for Industry 4.0?

A digital twin is a virtual replica of a physical object, process, or system that allows for its simulation, analysis, and real-time control. These digital representations are created using data from sensors installed on the physical object, which allows monitoring its status, predicting failures, and optimizing its performance. Digital twins span from industrial machinery and buildings to supply chains and manufacturing processes.

How do Digital Twins unlock the potential of Industry 4.0?

1. Real-time Monitoring

Digital twins enable continuous monitoring of physical assets, providing real-time data on their operations. This facilitates early identification of problems and implementation of solutions before they become critical failures.

2. Process Optimization

By simulating different scenarios and analyzing the results, companies can optimize their production processes. This results in increased operational efficiency, cost reduction, and improvement in product quality.

3. Predictive Maintenance

Through the analysis of historical and real-time data, digital twins can predict when equipment needs maintenance, thus avoiding unplanned downtime and extending the life of assets.

4. Innovation and Development

Digital twins allow testing and validating new designs and processes in a virtual environment before implementing them physically. This accelerates the innovation cycle and reduces risks associated with introducing changes in the real world.

Applications in Industry 4.0

Digital twins are being adopted across various industries, each leveraging their capabilities in different ways:

Manufacturing

In manufacturing, digital twins are used to monitor and optimize production lines, improve supply chain management, and enable mass customization.

Automotive

Automotive companies use digital twins to simulate and test new vehicle models, improve component design, and monitor the performance of vehicles in use.

Energy

In the energy sector, digital twins help optimize the operation of power plants, manage distribution networks, and predict energy demand.

Construction

Digital twins are used in construction to manage projects more efficiently, enhance planning, and provide detailed progress tracking.

Challenges and Future of Digital Twins and Industry 4.0

Despite its numerous benefits, the adoption of digital twins in Industry 4.0 also faces challenges. Integrating heterogeneous systems, ensuring data quality, and addressing cybersecurity are some of the main concerns. However, as these technologies evolve and businesses recognize their value, digital twins in Industry 4.0 are expected to play an increasingly central role.

In the future, combining digital twins with emerging technologies like artificial intelligence and blockchain will open up new possibilities. For example, AI can enhance the predictive capabilities of digital twins, while blockchain can ensure data integrity.

Perhaps you might be interested: Digital twins and AI: transforming industrial operations

Digital twins represent a significant opportunity for companies seeking to maximize the potential of Industry 4.0. By providing a window into the internal workings of assets and processes, they enable more informed and agile decision-making. While there are challenges to overcome, the future of digital twins is promising, with the potential to transform entire industries and elevate efficiency and innovation to new heights.

JOIN THE NEW REALITY!