Mantenimiento Predictivo: La Clave para Evitar Fallos y Optimizar la Producción

What Is Predictive Maintenance and How Does It Outperform Preventive Maintenance?

Predictive maintenance is an advanced industrial asset management strategy based on real-time data analysis to anticipate failures before they occur. Unlike preventive maintenance (which operates on a calendar), predictive maintenance uses sensors, artificial intelligence, and digital modeling to intervene only when truly necessary.

This allows metallurgical plants, logistics centers, and factories to reduce downtime, avoid unplanned interruptions, and extend the lifespan of their most critical equipment. Body

Is your plant still using traditional maintenance? Schedule a digitalization diagnosis with Foundtech. .

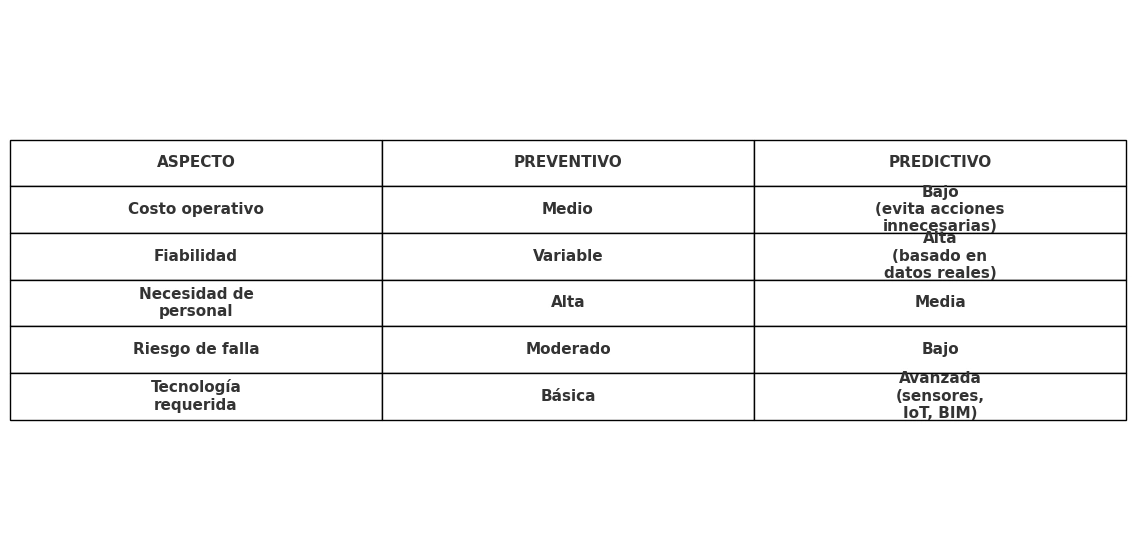

Predictive vs. Preventive: Why This Is a New Era

Preventive maintenance: Based on regularly scheduled maintenance regardless of the equipment’s actual condition.

Preventive maintenance: Based on regularly scheduled maintenance regardless of the equipment’s actual condition.

Want to reduce your maintenance costs by up to 30%? Discover more about BIM

Predictive Maintenance Features for Industry 4.0

In the context of Industry 4.0, predictive maintenance is not just an improvement—it’s a strategic necessity.

Key features:

– Integration with digital twins: 3D visualization of the actual condition of equipment and facilities.

– Continuous monitoring: IoT sensors collect real-time data.

– Machine learninAlgorithms analyze wear patterns and predict failures.

– Automated alerts: Connected systems notify before a component fails.

This approach reduces the risk of unplanned downtime—one of the industry’s highest hidden costs.

Tools for Predictive Quality Control

The success of predictive maintenance depends on having the right tools for quality control and data analysis:

– Sensores IoT: Para temperatura, presión, vibración, flujo, humedad.

– BIM management platforms: To model and visualize equipment conditions.

– Monitoring dashboards: Power BI, SCADA, or other visualization systems.

–Artificial intelligence: Trained models to identify deviations or anomalies before they become failures.

And it all starts with a precise digital capture, using 3D laser scanning and BIM models like those we implement at Foundtech.

Conclusion: More Data, Fewer Failures

Predictive maintenance is redefining how industries operate, manage risks, and optimize assets. It’s no longer just about keeping a machine running—it’s about anticipating, measuring, simulating, and making precise decisions.

At Foundtech, we combine laser scanning, BIM modeling, and predictive analysis tools to take your plant or warehouse to the next level. Because in an environment where every error costs, data-driven anticipation is the new standard of industrial quality.

Ready to stay ahead of failures and reduce your unplanned downtime?