Remodeling with Scan to BIM: How to Transform Existing Buildings with 3D Scanning and Accurate BIM Models

Why is it important to understand remodeling with scan to BIM? You might need it—imagine this:

The building in front of you is over 50 years old and urgently needs renovation, but the original blueprints were lost decades ago. Sound familiar?

It’s a common scenario architects and engineers constantly face when taking on remodeling projects in existing buildings.

Until recently, documenting a structure’s current state meant weeks of manual measurements, rough sketches, and headaches trying to create accurate as-built plans. But technology has revolutionized this process: combining 3D scanning with the scan to BIM methodology is transforming the way we digitize and modernize infrastructure.

At Foundtech, we’ve seen how creating BIM models from point clouds not only speeds up renovation projects, but also minimizes costly errors and enables more informed decision-making. Imagine being able to virtually navigate an exact replica of your building before moving a single brick.

In this guide, we’ll walk you through how scan to BIM technology is revolutionizing the documentation of existing buildings—and why it has become an essential tool for any modern renovation project.

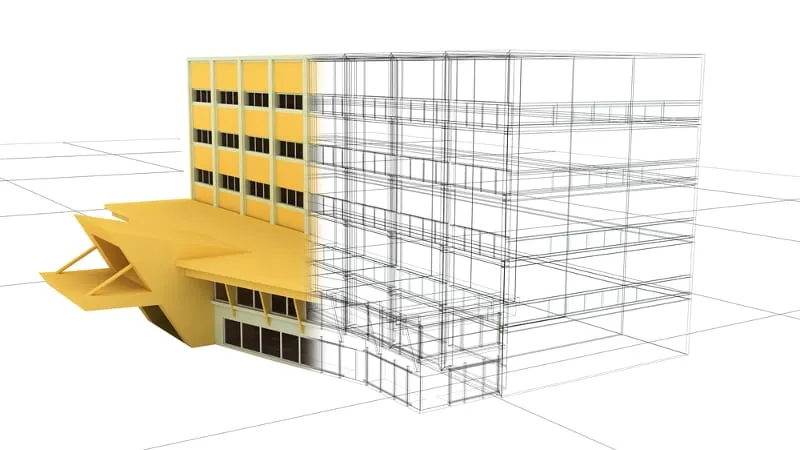

What Is Scan to BIM and How Does It Transform Remodeling?

Scan to BIM is a methodology that combines 3D laser scanning with Building Information Modeling (BIM) to create accurate digital representations of existing buildings. This process transforms millions of data points captured by laser scanners into intelligent, parametric BIM models.

The transformation takes place in three key phases:

Data Capture: Laser scanners—such as Faro Focus or Leica RTC360—emit light pulses that measure distances with millimeter precision. In a typical scanning session, up to 2 million points per second can be captured, generating a dense point cloud that represents every surface, structural element, and architectural detail.

Point Cloud Processing: The data is processed using specialized software like Recap Pro or CloudCompare, where noise is removed, multiple scans are aligned, and the information is optimized for further modeling.

BIM Modeling: Using platforms like Revit, ArchiCAD, or Tekla, specialists create parametric BIM models based on the point cloud, incorporating semantic information about materials, systems, and construction components.

This methodology reduces architectural survey time from weeks to days, improving accuracy from 85% (traditional methods) to 99.5%, according to AEC industry studies.

Technical Process: From 3D Scanning to Detailed BIM Models

Phase 1: Planning and Data Capture

The technical process begins with a strategic planning of the survey. Specialists determine optimal scanning positions based on the building’s geometry, visual obstructions, and the required level of detail.

During capture, scanning stations are placed every 10–15 meters indoors and 20–30 meters outdoors. Each station generates a local point cloud that is later integrated using reference targets or automatic registration algorithms.

Modern scanners like the Faro Focus S350 capture up to 1 million points per second with ±1mm accuracy, generating files between 50–200 GB for a typical remodeling project.

Phase 2: Processing and Optimization

Data processing involves multiple technical stages:

Point cloud registration: Aligning multiple scans using common control points

Noise filtering: Removing erroneous data caused by reflective surfaces or movement

Smart decimation: Reducing point density while retaining critical modeling information

Segmentation: Automatic classification of structural, MEP, and architectural elements

Phase 3: Parametric BIM Modeling

Creating BIM models from point clouds requires specialized technical expertise. Modelers use tools such as:

Revit with CloudWorx plugins: For architectural and structural modeling

– Tekla Structures: Especializado en elementos de acero y concreto

ArchiCAD: Optimized for parametric architectural design

The result is BIM models that include geometric information, material properties, technical specifications, and metadata for facility management.

Benefits of As-Built Plans in Existing Buildings

As-built plans generated through scan to BIM offer measurable advantages that directly impact the success of remodeling projects:

Superior Dimensional Accuracy

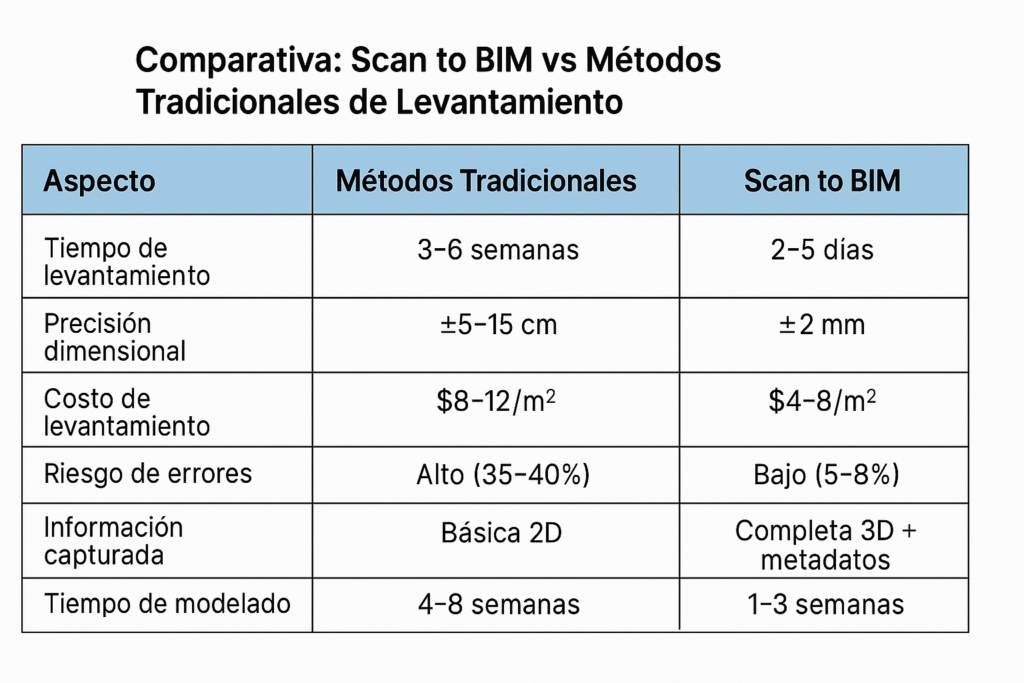

Traditional as-built plans show average deviations of 5–15 cm compared to the actual built environment. In contrast, BIM models generated via 3D scanning maintain accuracies of ±2 mm, reducing construction conflicts by 78%, according to McGraw Hill Construction data.

Early Clash Detection

BIM models help identify clashes between MEP systems, structural elements, and new installations before construction begins. This clash detection capability prevents rework, which accounts for 12–15% of total costs in remodeling projects.

Accurate Quantity Takeoffs

The parametric information in BIM models enables automatic extraction of quantities with 95–98% accuracy. This level of precision improves cost estimation and reduces project contingencies from 20% to an average of 8%.

Comprehensive Documentation of Hidden Systems

3D scanning captures information on visible MEP systems, exposed piping, and structural elements not shown in original blueprints. This documentation is crucial to avoid damage to existing systems during remodeling.

Comparison: Scan to BIM vs. Traditional Survey Methods

Technical Advantages of Scan to BIM

Non-invasive capture: Laser scanning doesn’t require physical access to all areas, enabling documentation of hard-to-reach spaces such as mezzanines, high façades, or restricted zones.

Complete documentation: Each scan captures texture, color, and surface condition data alongside 3D geometry, providing invaluable visual context for design decisions.

Digital traceability: BIM models retain links to the original point cloud, allowing later verification and incremental model updates.

Limitations of Traditional Methods

Manual surveys face inherent limitations:

Operator subjectivity: Measurements depend on individual skill and judgment

Limited access: Inability to document inaccessible or hazardous spaces

Cumulative errors: Sequential measurements amplify inaccuracies

Incomplete data: Difficulty capturing complex or irregular geometries

Scan to BIM eliminates these limitations through objective capture, remote access, and exhaustive documentation of complex geometries.

Practical Implementation: Tools and Workflowsl Scan to BIM

Choosing Scanning Equipment

The choice of laser scanner determines the quality and efficiency of the project. Scanners are categorized into three types:

Long-range scanners (100–300m): Ideal for façades and large outdoor areas. Models like the Faro Focus S350 or Leica ScanStation P50 offer ±1mm precision and 1 million points/second speed.

Mid-range scanners (50–100m): Versatile for medium-sized interiors and exteriors. The Faro Focus S70 combines portability with ±2mm accuracy, optimizing productivity in remodeling projects.

Short-range scanners (10–50m): Specialized for detailed interior spaces. Devices like the Leica BLK360 prioritize fast setup and ease of use for architectural surveys.

Specific Use Cases in Remodeling

Heritage Building Renovation

Historic buildings present unique challenges that scan to BIM efficiently addresses:

Irregular geometries: Non-orthogonal walls, complex vaults, unique decorative elements

Nonexistent documentation: Missing or inaccurate original blueprints

Access restrictions: Limitations on invasive measurement in protected structure

Required accuracy: Need to document architectural details with millimetric precision

A typical heritage renovation project reduces documentation time from 8–12 weeks to just 2–3 weeks, while maintaining over 99% accuracy.

Modernization of Industrial Facilities

Industrial plants require precise documentation of complex MEP systems:

Piping and ductwork: 3D tracing of existing installations

Industrial equipment: Exact geometry of machinery and mechanical components

Steel structures: Documentation of connections, welds, and deformations

Confined spaces: Remote access to areas difficult to reach physically

Expansions and Additions

Expansion projects benefit from scan to BIM through:

Structural connections: Accurate identification of anchoring and connection points

Architectural continuity: Documentation of details to maintain aesthetic consistency

Service interferences: Detection of clashes with existing installations

Levels and elevations: Precise referencing for new construction work

Conclusion

In an environment where every centimeter matters and errors translate into cost overruns, Scan to BIM represents more than just a technical improvement—it’s a paradigm shift. It’s no longer about guessing with imprecise drawings, but about building with real data, intelligent models, and well-informed decisions from day one.

At Foundtech, we believe that remodeling shouldn’t feel like a leap into the unknown. With high-precision 3D scanning and detailed BIM models, we help your projects progress with fluidity, coordination, and complete control. Because transforming an existing building doesn’t start with demolition… it starts with information.