5 Reasons Why Companies Need to Invest in Digital Simulation

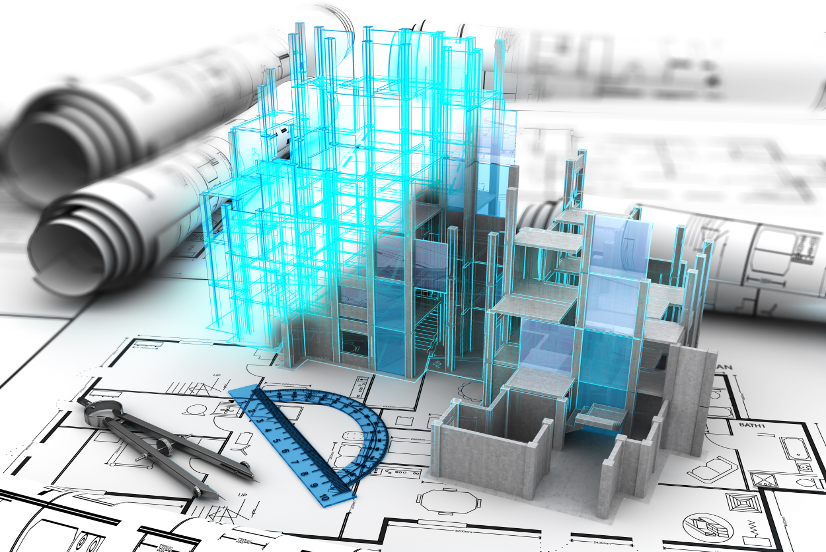

In the digital era, companies face an increasingly competitive and dynamic environment. To stay ahead, many are turning to digital simulation—a strategic tool that encompasses technologies such as digital twins, BIM (Building Information Modeling), augmented reality (AR), and virtual reality (VR). This technology enables organizations to optimize operations, reduce costs, and foster innovation. Here are the key reasons why companies should seriously consider investing in digital simulation.

1. Increased Productivity and Efficiency

One of the main advantages of digital simulation, particularly through digital twins, is its ability to simulate processes and products in a virtual environment before physical implementation. This not only enhances operational efficiency but also identifies areas for improvement and optimization within production processes. Studies have shown that digital simulation can boost productivity by up to 20% and significantly reduce time to market, enabling companies to launch products faster and more efficiently.

How It Impacts Productivity:

- Digital models allow for the forecasting and optimization of workflows.

- Different production configurations can be tested without risking resources.

- Bottlenecks can be eliminated before they occur in the real world.

The use of BIM also plays a crucial role in planning and visualizing construction projects or product development, increasing productivity by improving coordination among multidisciplinary teams.

2. Cost Reduction

One of the biggest barriers companies face when innovating is the cost of physical prototypes. With digital simulation, companies can perform virtual tests without needing to create physical products, significantly reducing costs associated with research and development.

Cost Benefits:

- Lower product development costs through simulations prior to production.

- Process optimization without the need for physical experimentation.

- Minimized financial risk by testing strategies without committing physical resources.

This cost-saving impact extends beyond the development phase to continuous production, where areas for improvement can be identified in the supply chain and operations.

Improved Decision Making

Los gemelos digitales permiten a las empresas obtener datos en tiempo real sobre el rendimiento de los activos y procesos. This provides business leaders with accurate information to make strategic and operational decisions.

La capacidad de monitorear constantemente los activos y simular diversos escenarios antes de tomar una decisión real es invaluable para reducir el riesgo y optimizar la eficiencia.

Advantages in Decision Making:

- Informed and timely decisions enabled by real-time data.

- Identification of potential failures before they occur, reducing downtime.

- Proactive implementation of adjustments without interrupting production.

Technologies like AR and VR in simulations provide a clearer visualization of processes, facilitating complex decision-making.

4. Innovation and Adaptability

The ability to experiment with new processes, products, or solutions without risk is one of the greatest appeals of digital simulation. Companies can test different scenarios and explore new ideas in a virtual environment, fostering a continuous cycle of innovation. This is especially relevant in highly competitive markets, where the ability to quickly adapt to market changes is crucial.

Encouraging Innovation:

- Simulations enable the testing of innovative ideas without the risks associated with physical production.

- Companies can quickly adapt to market needs.

- Technologies like VR and AR offer an immersive space to create prototypes of products or facilities.

By allowing teams to face different scenarios without the costs of failure, companies can stay ahead in creating innovative products and services.

5. Safety and Risk Reduction

Virtual Reality (VR) and Augmented Reality (AR) are increasingly being used to train employees in a safe environment. Through simulations of complex or hazardous situations, workers can gain hands-on experience without the risks associated with handling dangerous machinery or processes.

Safety Benefits:

- Risk-free training: Employees can safely practice procedures in virtual environments before facing real situations.

- Reduction in workplace accidents: Simulations familiarize workers with safety protocols and potential risks without real-world exposure.

- Virtual machinery prototypes: Operators can practice with machine and system models without the risk of damaging real equipment.

This not only enhances workplace safety but also ensures companies comply more effectively with safety regulations.

Conclusion

In a fast-paced business world, digital simulation has become an indispensable tool for companies looking to stay competitive. Whether through digital twins, BIM, or AR and VR technologies, digital simulation offers numerous benefits, from resource optimization to better decision-making and fostering innovation. Investing in these technologies not only improves operational efficiency but also enables companies to reduce costs, minimize risks, and remain agile in the face of market changes.

Are you ready to take your business to the next level with digital simulation?

JOIN THE NEW REALITY!