Why Are Digital Factories the Future of Manufacturing?

Digital Factories are revolutionizing manufacturing by integrating advanced technologies that transform production processes. Below are the key reasons why these factories are considered the future of the manufacturing industry.

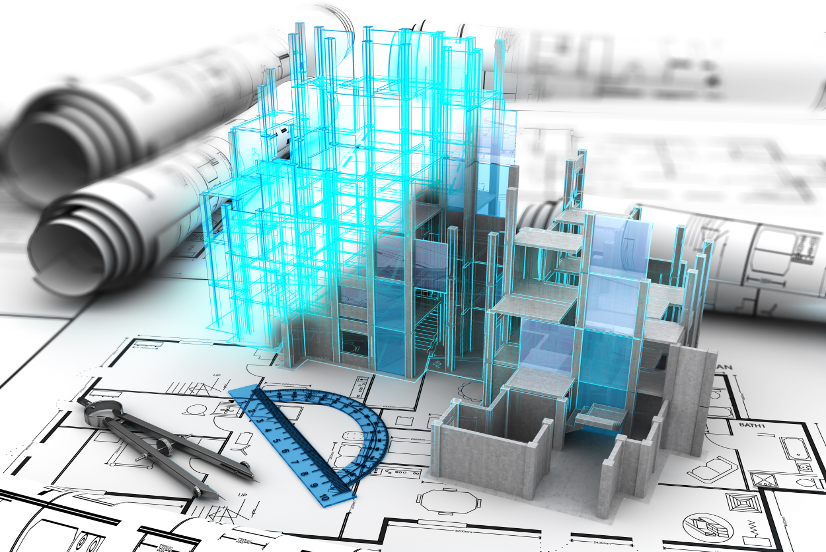

What are Digital Factories?

Digital Factories are production environments that integrate advanced and digital technologies to optimize manufacturing processes. These factories represent a significant shift in the way products are designed, produced and distributed, leveraging connectivity and automation to improve efficiency and sustainability.

Characteristics:

1. Connectivity and Automation: Digital Factories use the Internet of Things (IoT) to connect machines, sensors and information systems, enabling fluid communication between all components of the supply chain. This facilitates monitoring and optimization of processes in real time.

2. System Integration: These factories integrate various management systems, such as Manufacturing Execution System (MES), Product Lifecycle Management (PLM), and Enterprise Resource Planning (ERP). This integration enables a holistic view of operations, improving decision-making and planning.

3. Data Utilization and Analysis: The ability to collect and analyze large volumes of data allows companies to identify patterns, predict issues, and optimize production. This translates into greater flexibility and responsiveness to changes in market demand.

Benefits of Digital Factories

– Improved Efficiency: Automation and process optimization lead to faster and more cost-effective production.

– Cost Reduction: By improving efficiency and reducing waste, Digital Factories can significantly lower operational costs.

– Enhanced Product Quality: Real-time monitoring and data usage enable the proactive detection and correction of quality issues.

– Adaptability: These factories can quickly adjust to changes in demand, which is crucial in a dynamic market environment.

Reasons why they are the Future of Manufacturing

They are the future of the manufacturing industry for the following reasons:

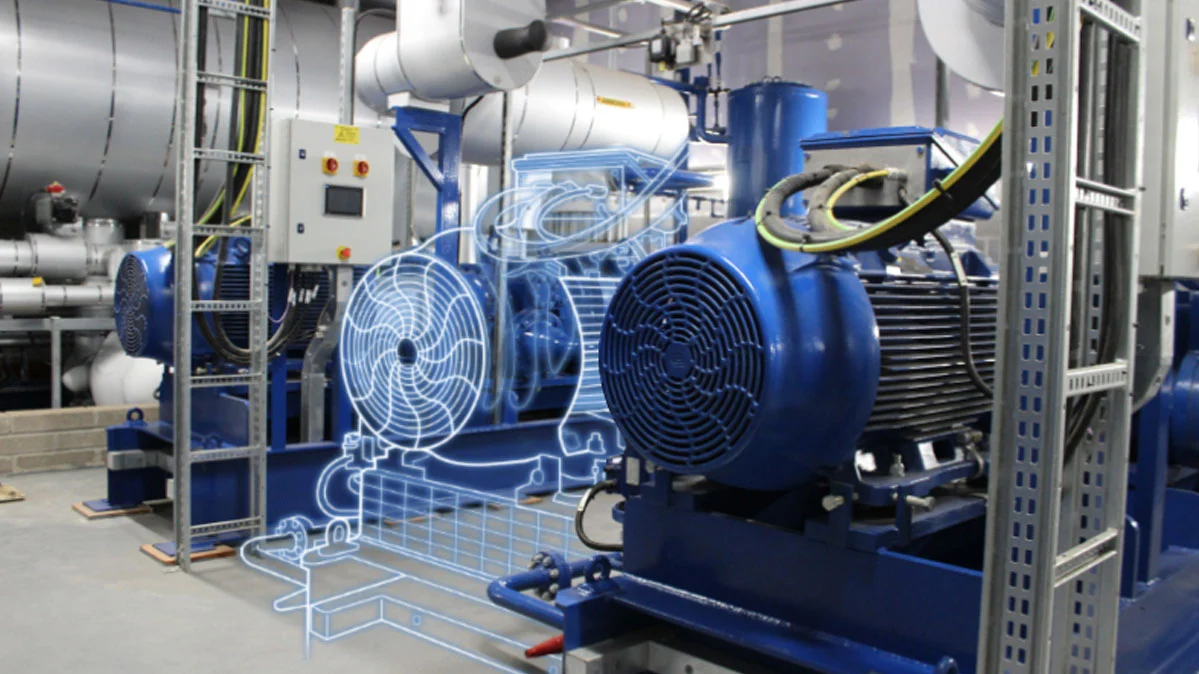

- Integration of Advanced Technologies

Digital Factories leverage technologies such as the Internet of Things (IoT), artificial intelligence (AI), data analytics, and automation to optimize operations. This integration enables manufacturers to be more flexible and quickly adapt to changes in market demand, thereby improving their competitiveness.

- Efficiency and Sustainability

Digital factories enable better resource management, reducing energy and material consumption. This translates into more sustainable production, aligned with current consumer expectations and environmental regulations . Additionally, the minimization of waste through the use of simulations and digital modeling contributes to a cleaner and more efficient production cycle.

- Improved Decision Making

Digital Factories facilitate real-time data collection and analysis, enabling business leaders to make more informed and strategic decisions. The ability to connect different systems provides a holistic view of operations, enhancing the ability to respond to changes in the business environment. This translates into greater agility and precision in decision-making.

In summary, Digital Factories are the future of manufacturing because they combine efficiency, sustainability, and adaptability. By integrating advanced technologies, optimizing resource management, and improving decision-making, these factories enable companies not only to survive but to thrive in an ever-evolving industrial environment.

If you liked this post, you might also like: Optimiza el Mantenimiento: Gemelos Digitales, IA y más

In conclusion, digital factories represent a revolution in manufacturing that promises to transform the industry and meet the growing demands of the market in an efficient and sustainable manner.

JOIN THE NEW REALITY!