History of Digital Twins in Industry: Past and Future

In the world of industry, technology continues to advance by leaps and bounds. One of the most fascinating and promising innovations in this field is the concept of digital twins. These virtual replicas of physical objects, processes, or systems are already revolutionizing the way products and infrastructures are designed, operated, and maintained. In this article, we will explore the past and future of the digital twin industry, and how it has transformed the way we work and live.

The Past: History of Digital Twins

While the concept may seem innovative, the history of digital twins dates back decades. The earliest digital models emerged in the aerospace and automotive industries in the 1970s and 1980s, primarily used for simulations.

In the 1980s, NASA developed simulations for its spacecraft and equipment, motivated by the Apollo 13 mission accident in 1970. This incident inspired the creation of digital twins to test real-time survival solutions. For example, when carbon dioxide levels on Apollo 13 became dangerous, a oxygen purification system was designed from materials available on the spacecraft in Houston, and instructions were sent to the astronauts to build it in space.

However, the term “digital twin” did not become popular until 2003 when computer engineer Michael Grieves introduced it at a conference at the University of Michigan on product lifecycle management (PLM).

These early digital twins laid the groundwork for what would come next, but their scope and sophistication were limited compared to current capabilities.

Over time and with the advancement of technologies such as Big Data, IoT, and cloud storage, the scope of Industry 4.0, digital twins history has expanded to other fields and sectors, leading to significant evolution.

The Present: Applications and Benefits

Now, these virtual representations are capable of accurately capturing even the most intricate details of physical objects and complex processes. Moreover, they are integrating real-time data to provide a more dynamic and precise view of reality.

Digital twins are presented as a disruptive technology in the simulation and analysis of industrial processes, allowing for the prediction of process flows and early decision-making to correct errors before they occur. This advancement has been made possible by the consolidation of the Internet of Things (IoT) in Industry 4.0 and advances in high-volume storage techniques and machine learning through Big Data Analytics.

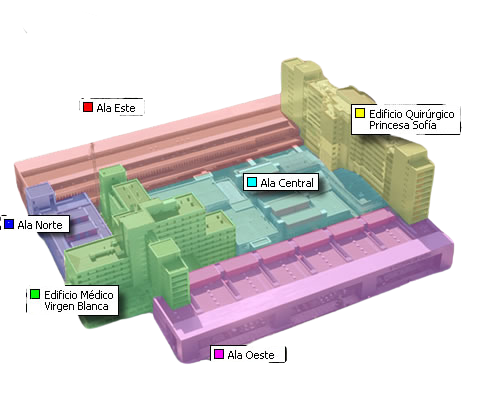

The growth and development of digital twins have been significant in recent years, especially in the context of Industry 4.0. Today, digital twins have applications in a wide range of industries, from manufacturing and construction to healthcare and transportation.

You might be interested: Digital Twins in Real Life: Examples.

The benefits of digital twins are abundant. They enable more informed and agile decision-making, facilitate collaboration between geographically dispersed teams, and help prevent failures and accidents through early detection of potential problems. Additionally, they are paving the way for the creation of new business opportunities and service models, driving innovation and economic growth.

The Future: Challenges and Opportunities

As digital twins continue to evolve, they also face significant challenges. One of the biggest challenges is interoperability between different platforms and systems, as data must flow seamlessly and securely between the physical and virtual worlds. Additionally, data privacy and security are growing concerns as the amount of collected and shared information increases.

However, despite these challenges, the future of digital twins is promising. Their adoption is expected to continue growing in the coming years, driven by advances in areas such as the Internet of Things (IoT), cloud computing, and data analytics. As digital twins become more accessible and affordable, we are likely to see an even greater proliferation of innovative applications and use cases in all industries.

In conclusion, digital twins’ history is navigating between the industry’s past and future, transforming how we conceive, design, and operate the world around us. With their ability to integrate data, simulate scenarios, and make informed decisions, digital twins are paving the way toward a smarter, more efficient, and sustainable future.

JOIN THE NEW REALITY!