What is a digital twin?: benefits and applications

Join the new reality!: Why Digital Twins will dominate Industry 4.0

Wondering what a digital twin is? You’ve come to the right place! The Digital Twins are destined to become a foundational pillar of digital transformation. According to projections from Gartner, the global Digital Twin market will surpass USD 183 billion by 2031..

What is a Digital Twin?

What is a Digital Twin? is a dynamic virtual replica of a real-world object, system, or process. It integrates real-time data to simulate, predict, and optimize the performance of physical assets throughout their lifecycle. This innovation impacts sectors as diverse as aerospace, manufacturing, ,construction, and strategic procurement.. The term “Digital Twin” will become ubiquitous in the coming decade.

If you’re exploring this topic for the first time, welcome to our introductory article, where we’ll break down what a Twin really is and what its fundamental applications are. If you’d like a quote or personalized consultation, contact us.

DIGITAL TWIN = GEMELO DIGITAL

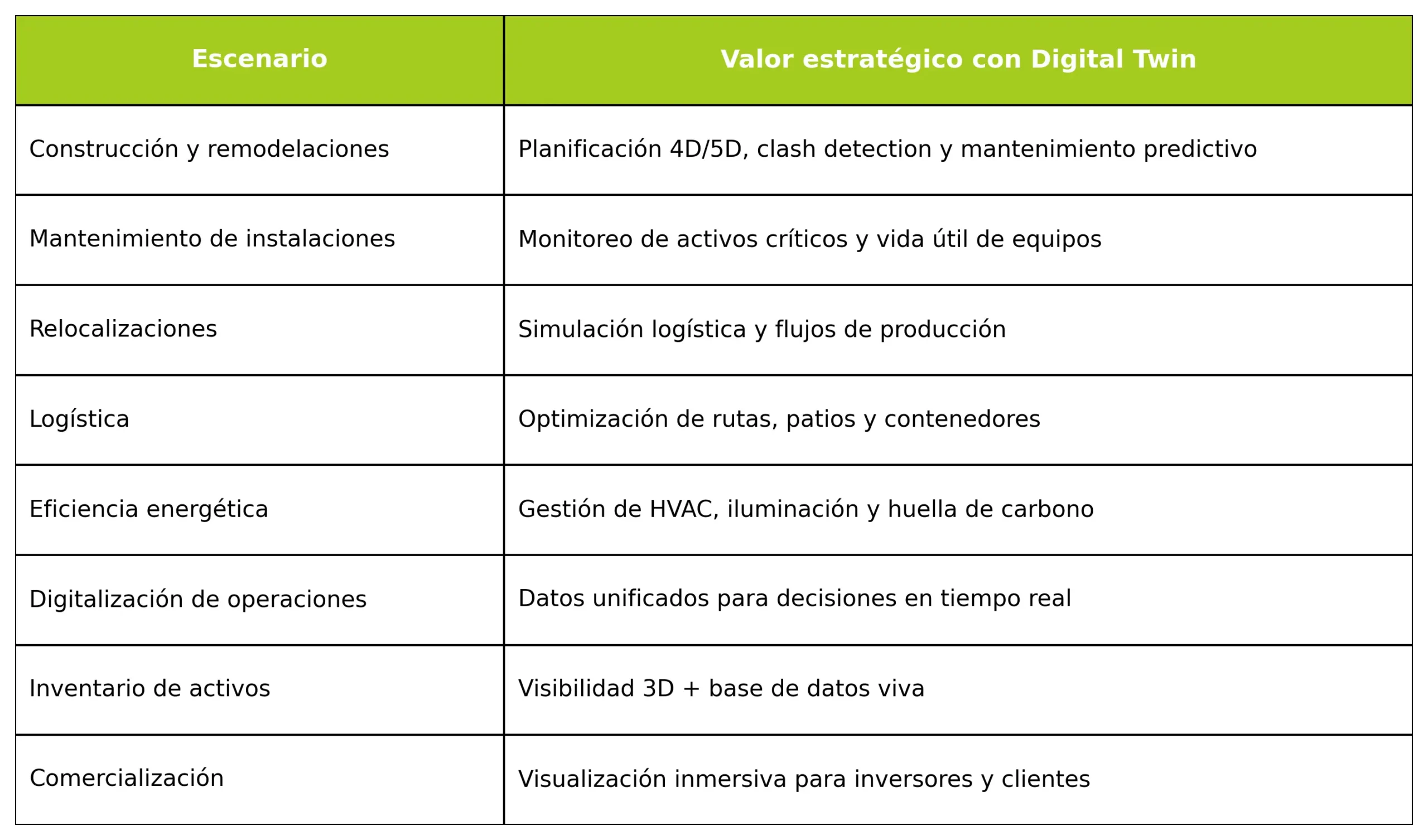

Below are some scenarios in which we can be your strategic allies, defining unique, innovative solutions with high operational efficiency impact.

Industries where we already use Digital Twins

Want to stay up to date? Read the latest news about Digital Twins across multiple industries.

[See news]

Key benefits of a Digital Twin

The benefits of a Digital Twin are diverse and can significantly impact a wide range of industries and applications. Some of the key benefits include:

Accurate 3D Visualization: Provides a precise virtual representation of real-world objects, systems, or processes, facilitating understanding and informed decision-making.

Predictive Maintenance: Enables you to anticipate and address maintenance issues before they become costly operational interruptions, increasing availability and reliability.

Simulation and Experimentation: Allows you to test different scenarios and strategies in a risk-free virtual environment, enabling innovation and continuous improvement.

Risk Reduction: Lets you assess and mitigate risks in a virtual space before real-world implementation, minimizing potential hazards.

Continuous Optimization: Identifies inefficiencies and areas for improvement, leading to more efficient management, cost reduction, and higher quality.

Time and Resource Savings: Reduces the time and resources needed to design, develop, and test products and processes, speeding up time-to-market.

Data-Driven Decision Making:

Provides up-to-date, accurate information for informed decisions, reducing the risk of costly mistakes.Innovation and Experimentation:

Fosters innovation by enabling experimentation with new ideas and technologies in a safe virtual environment, encouraging best practices.Enhanced Collaboration:

Facilitates collaboration among teams and stakeholders by providing a shared representation of reality, improving communication and coordination.Efficient Asset Management:

Enables asset management across their lifecycle—from design and production to maintenance and decommissioning—maximizing asset value.Sustainability: Contributes to more sustainable practices by reducing waste, optimizing resource use, and improving energy efficiency.

The Future of the Digital Twin

The potential of Digital Twins is virtually limitless. With greater cognitive power, these models continuously learn and expand their analytical capabilities, becoming the backbone of Industry 4.0.

Success Stories

Millas Migros (BrownField): Se midió el stock completo y se modeló un diseño BIM a partir de escaneos 3D, logrando grandes beneficios operativos.

Cine Metropol, Zürich: Renovación digital del cine con modelo BIM a partir de 200 escaneos. Space optimization, cost reduction, and risk minimization.

Cine Metropol, Zürich: Renovación digital del cine con modelo BIM a partir de 200 escaneos. Space optimization, cost reduction, and risk minimization.

Fröh Verpackungstechnik AG: Time, costs, and operational risks were reduced by generating an accurate as-built of the site, optimizing planning and execution.

Fröh Verpackungstechnik AG: Time, costs, and operational risks were reduced by generating an accurate as-built of the site, optimizing planning and execution.

Werdhölzli Wastewater Treatment Plant (Switzerland): Complete digital modernization of the plant. The digital twin enabled precise planning and supported future maintenance and operations.

Werdhölzli Wastewater Treatment Plant (Switzerland): Complete digital modernization of the plant. The digital twin enabled precise planning and supported future maintenance and operations.

Claraspital (Basel, Switzerland): A Digital Twin was developed for the hospital’s renovation. Over 2,500 spaces were scanned, and all infrastructures—including gas, pneumatic, and liquid systems—were modeled in BIM.

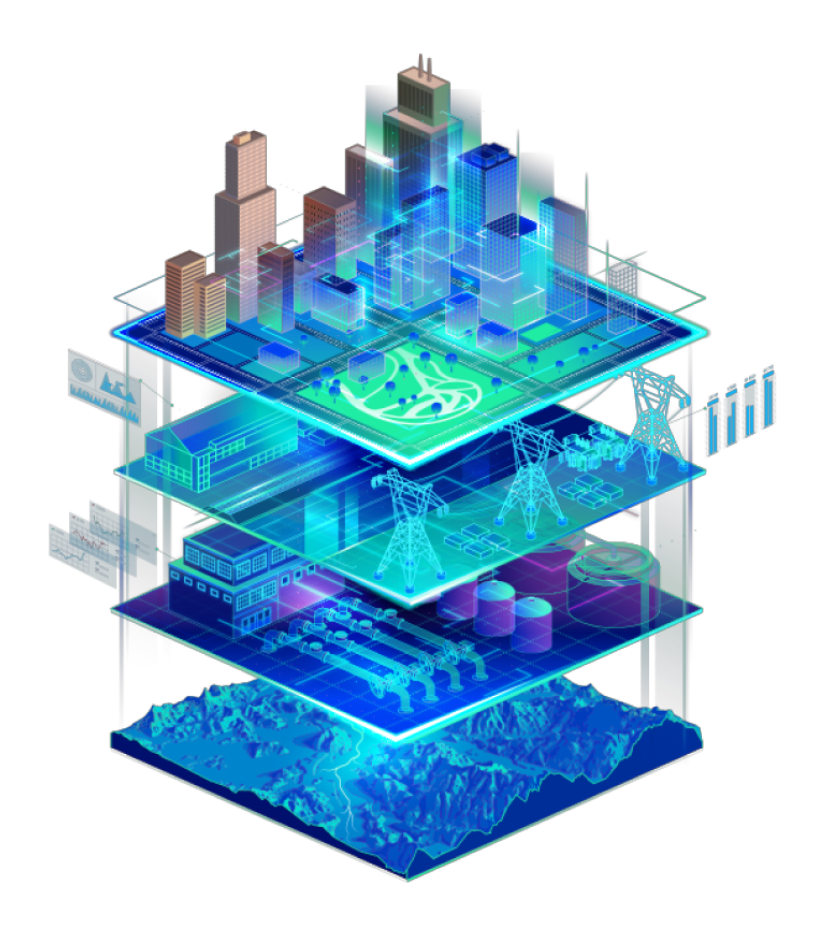

How a Digital Twin Works

- Physical Twin:Real-world objects, processes, and systems.

- Data Collection: Sensors, 3D scanning, IoT, BIM.

- Digital Twin: Representative models, data management, and analytics.

- Information & Decisions: Continuous feedback to the physical world.

Ready for your Digital Twin?

At Foundtech, we define unique, innovative solutions with high impact on operational efficiency. From the initial scan to the launch of your digital twin. Request a consultation.

Join the new digital reality and optimize your operation starting today!